Table of Contents

- Introduction to SIL Study

- What is Safety Integrity Level (SIL)?

- Importance of SIL in Process Safety

- Standards and Guidelines Referencing SIL

- Key Terms and Definitions

- SIL Determination Methods

- Risk Graph Method

- Layer of Protection Analysis (LOPA)

- Fault Tree Analysis (FTA)

- SIL Levels Explained (SIL 1 to SIL 4)

- SIL Lifecycle Phases

- SIL Verification and Validation

- SIL Study Documentation and Reporting

- Common Challenges in SIL Assessment

- SIL and Functional Safety: Relationship with IEC 61508/61511

- Software Tools for SIL Assessment

- SIL in Real-World Applications (Industry Examples)

- SIL Implementation Checklist

- SIL vs Other Risk Reduction Methods

- Expanded Software Tools Comparison

- Functional Safety Assessment (FSA) in SIL

- Advanced FAQs

- Conclusion: Key Takeaways

1. Introduction to SIL Study

In the hazardous world of chemical processing, oil and gas, power plants, and pharmaceuticals, managing risk is paramount. One of the most reliable methodologies in ensuring functional safety is the Safety Integrity Level (SIL) study. It evaluates the performance requirements of Safety Instrumented Functions (SIFs) to reduce risks to acceptable levels.

This guide serves as a detailed manual for understanding, conducting, and validating SIL studies in line with international best practices.

2. What is Safety Integrity Level (SIL)?

SIL is a relative level of risk-reduction provided by a Safety Instrumented Function (SIF), or the level of risk-reduction required. Defined by the IEC 61508 and IEC 61511 standards, it ensures that a system performs safely on demand.

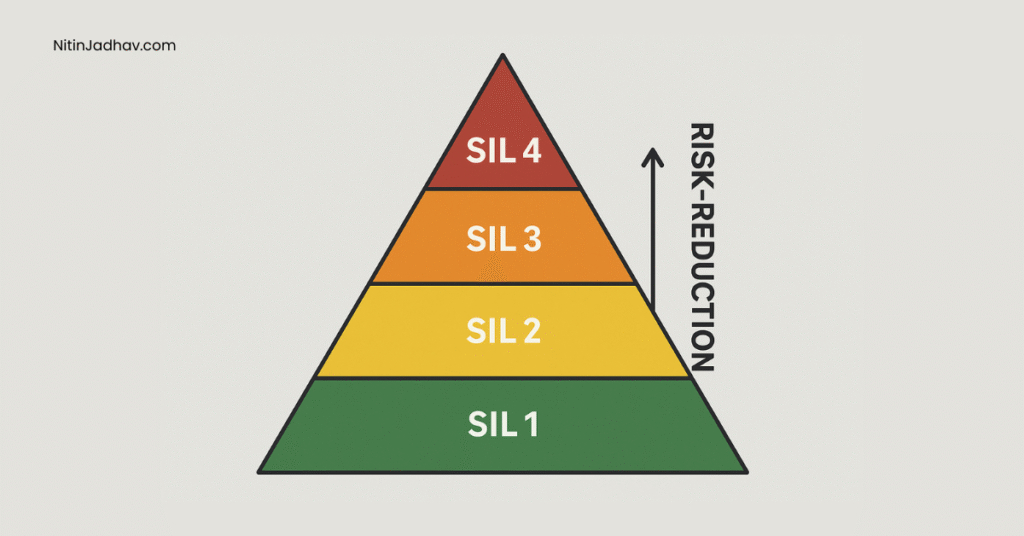

Each SIL level corresponds to a range of Probability of Failure on Demand (PFD), ranging from SIL 1 (lowest) to SIL 4 (highest). The higher the SIL level, the more stringent the requirements.

3. Importance of SIL in Process Safety

- Ensures critical systems perform reliably

- Supports compliance with international standards (e.g., IEC 61511)

- Minimizes operational risks and protects life and environment

- Helps justify process safety investments to regulatory bodies and stakeholders

4. Standards and Guidelines Referencing SIL

- IEC 61508: Functional safety of electrical/electronic/programmable electronic safety-related systems

- IEC 61511: Functional safety for the process industry sector

- API 754: Process safety performance indicators

- ISA 84: Functional safety: Safety Instrumented Systems for the Process Industry Sector

- OISD-GDN-206: Indian guideline on SIL

External Source: IEC 61511 Overview – IEC

5. Key Terms and Definitions

- SIF (Safety Instrumented Function)

- SIS (Safety Instrumented System)

- PFDavg (Average Probability of Failure on Demand)

- Risk Reduction Factor (RRF)

- HFT (Hardware Fault Tolerance)

- MTTR (Mean Time to Repair)

6. SIL Determination Methods

Risk Graph Method

A qualitative tool that uses predefined graphs considering:

- Consequence

- Frequency of exposure

- Possibility of avoiding hazard

- Severity

Layer of Protection Analysis (LOPA)

A semi-quantitative method that evaluates:

- Initiating event frequency

- Independent Protection Layers (IPLs)

- Consequence severity

- Tolerable risk criteria

Read more: SIL vs LOPA – What’s the Difference?

Fault Tree Analysis (FTA)

A deductive, logic-based method for identifying possible failures and calculating the likelihood of a top event.

7. SIL Levels Explained (SIL 1 to SIL 4)

| SIL Level | Risk Reduction Factor (RRF) | PFDavg Range |

|---|---|---|

| SIL 1 | 10 to < 100 | ≥1E-2 to <1E-1 |

| SIL 2 | 100 to < 1,000 | ≥1E-3 to <1E-2 |

| SIL 3 | 1,000 to < 10,000 | ≥1E-4 to <1E-3 |

| SIL 4 | 10,000 to < 100,000 | ≥1E-5 to <1E-4 |

8. SIL Lifecycle Phases

- Conceptual Design

- Hazard and Risk Assessment

- SIL Determination

- SIS Design and Implementation

- Installation and Commissioning

- Operation and Maintenance

- Modification and Decommissioning

9. SIL Verification and Validation

- Performed during design and operation

- Ensures the SIS can achieve its intended SIL level

- Tools like exSILentia, SILSolver, and PILOT SIS are widely used

- Requires Failure Modes Effects and Diagnostic Analysis (FMEDA)

Related Article: HAZOP Study: A Detailed Guide

10. SIL Study Documentation and Reporting

A proper SIL study report should include:

- Executive summary

- SIF descriptions

- Methodology used (LOPA/Risk Graph)

- SIL assessment worksheets

- Assumptions and data references

- SIL verification calculations

11. Common Challenges in SIL Assessment

- Inadequate or incorrect input data

- Misunderstanding IPL effectiveness

- Underestimating human error probabilities

- Improper use of software tools

- Over-conservatism or over-design

12. SIL and Functional Safety: Relationship with IEC 61508/61511

- IEC 61508 is generic, applicable to all E/E/PE safety systems

- IEC 61511 is tailored for the process industry

- Defines functional safety lifecycle

- SIL assessment is a key step in achieving functional safety compliance

13. Software Tools for SIL Assessment

Some popular tools include:

- exSILentia by exida

- SILver by Siemens

- SILSolver

- PIPENET (for integrated dispersion/risk calculations)

Related Tool: Hydraulic Calculations Using PIPENET

14. SIL in Real-World Applications (Industry Examples)

- Refineries: Reactor emergency depressurization systems

- Fertilizer Plants: Ammonia leak detection and isolation

- Pharmaceuticals: Reactor overpressure protection systems

- Oil & Gas Platforms: Blowdown and gas detection shutdown

Each of these installations uses various SIL-rated systems to ensure safety performance under critical conditions.

15. SIL Implementation Checklist

- Identify critical SIFs

- Perform hazard analysis (e.g., HAZOP)

- Determine required SIL using LOPA or risk graph

- Select appropriate technology

- Conduct SIL verification

- Integrate SIS into design

- Validate during commissioning

- Set up maintenance and proof testing

- Conduct periodic reassessments

16. SIL vs Other Risk Reduction Methods

| Criteria | SIL Systems | Passive Protection | Operator Training |

|---|---|---|---|

| Reliability | High (quantified) | Moderate | Low |

| Cost | Medium to High | Low to Medium | Low |

| Dependency on Human | Low | None | High |

| Quantifiable Reduction | Yes | Rarely | No |

17. Expanded Software Tools Comparison

| Software | Strengths | Best For |

|---|---|---|

| exSILentia | Complete lifecycle support, LOPA, SRS, verification | End-to-end SIL assessments |

| SILSolver | Detailed PFD and RRF analysis | Verification of existing SIFs |

| PILOT SIS | Lifecycle, compliance-focused | Safety compliance tracking |

| PIPENET | Integrated dispersion + hydraulics | Firewater and vent sizing + SIL inputs |

18. Functional Safety Assessment (FSA) in SIL

Functional Safety Assessments (FSA) are formal audits that confirm the integrity of safety lifecycle phases. IEC 61511 mandates FSAs at five different stages:

- FSA Stage 1: Conceptual design

- FSA Stage 2: Design and engineering

- FSA Stage 3: Installation and commissioning

- FSA Stage 4: Operation and maintenance

- FSA Stage 5: Modification and decommissioning

Each FSA stage requires independent evaluation to validate the assumptions, data, and engineering rigor applied in the respective phase.

19. Frequently Asked Questions (FAQs)

Q1: What is the difference between SIL and LOPA?

LOPA is a methodology used to determine required SIL levels. SIL is the result or target level achieved by SIFs.

Q2: Is SIL 4 commonly used in the process industry?

No. SIL 4 is rare due to extreme reliability requirements. Most applications are SIL 1 to SIL 3.

Q3: Can a single SIF achieve multiple SIL levels?

No. Each SIF is assessed for one specific SIL level based on its performance and reliability.

Q4: What if a SIF cannot meet the target SIL?

Options include:

- Revising process conditions

- Adding additional IPLs

- Selecting more reliable equipment

Q5: Is SIL applicable to manual actions?

Only if the manual action meets the criteria for being an Independent Protection Layer (IPL).

Q6: How often should SIL be reassessed?

Typically during PHA revalidations (every 3-5 years), or after major modifications.

Q7: Who is responsible for SIL determination?

It is typically a multidisciplinary team: process safety engineers, instrumentation experts, and operations personnel.

20. Conclusion: Key Takeaways

- SIL is critical for risk reduction in high-hazard industries

- Must follow a structured lifecycle (IEC 61511)

- Proper documentation and software tools are essential

- Common methods include LOPA and Risk Graph

- Verification is as important as determination

- FSAs are critical for lifecycle integrity

Related Reads on NitinJadhav.com:

External Learning Resources: