Table of Contents

- Introduction

- What is an Air Dispersion Study?

- Why Air Dispersion Modeling is Important

- Key Inputs for Air Dispersion Modeling

- Regulatory Standards and Guidelines

- Software Used in Air Dispersion Studies

- Types of Dispersion Models

- Methodology for Air Dispersion Studies

- Case Study: LPG Leak Dispersion from Storage Bullet

- Best Practices in Dispersion Modeling

- Common Pitfalls to Avoid

- FAQs

- Conclusion

- References & External Links

🔍 Introduction

In industrial environments—especially in oil & gas, chemical, and power sectors—air dispersion modeling is a critical activity for evaluating environmental and safety risks. Whether it’s a planned vent, a fugitive emission, or an accidental toxic release, understanding how pollutants disperse in the atmosphere is vital for decision-making.

This guide will walk you through the scientific basis, tools, standards, and practical steps of conducting an effective air dispersion study.

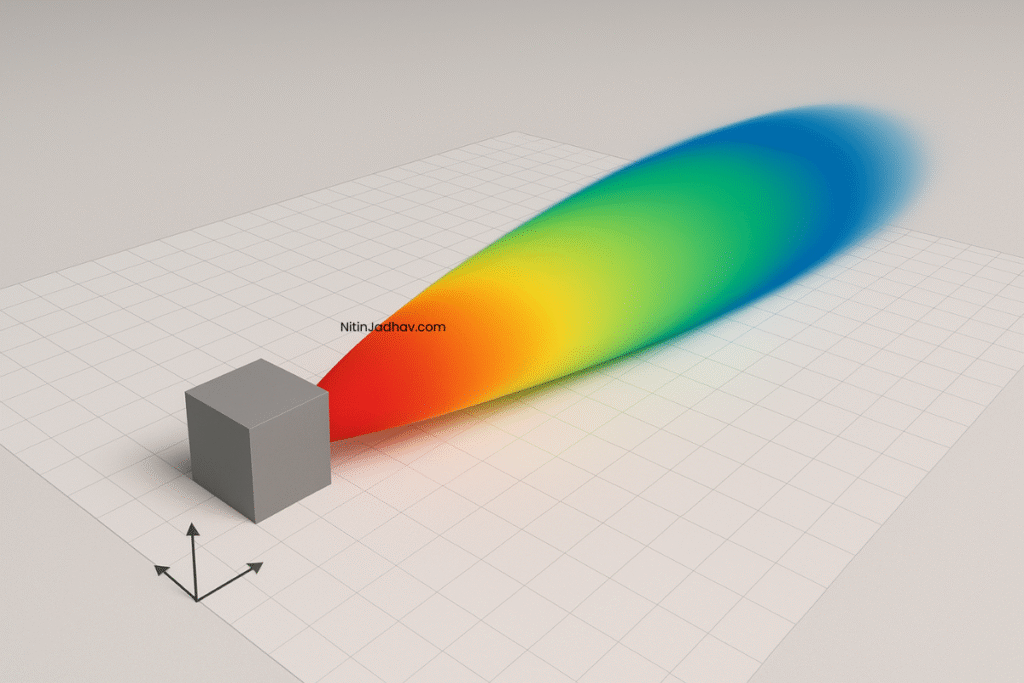

🌬️ What is an Air Dispersion Study?

An Air Dispersion Study is a scientific evaluation used to predict the spread of airborne pollutants released from a source into the environment. It uses mathematical models to simulate how contaminants like VOCs, H₂S, SOx, NOx, or particulates travel, dilute, and deposit in the surrounding atmosphere under varying conditions.

This analysis supports:

- Emergency response planning

- Environmental impact assessments

- Regulatory compliance (like CPCB, EPA, EEA)

- Safe plant layout and stack design

- HAZID/HAZOP and QRA studies

🎯 Why Air Dispersion Modeling is Important

Here’s why industries need to conduct these studies:

| Purpose | Explanation |

|---|---|

| 🔒 Process Safety | To estimate the toxic or flammable vapor cloud extent for accidental releases |

| 🌱 Environmental Compliance | To assess ambient air quality impacts of routine emissions |

| 🏭 Facility Design | To determine appropriate stack height or flare location |

| 🚨 Emergency Planning | To define exclusion zones and community impact areas |

| 📉 Risk Mitigation | To understand and reduce the consequence of worst-case releases |

You may also like:

👉 HAZOP Study – A Detailed Guide

👉 QRA – Quantitative Risk Assessment Explained

📥 Key Inputs for Air Dispersion Modeling

- Source Parameters:

- Type: point, area, volume, flare, ground-level

- Release rate (kg/s or Nm³/s)

- Temperature and velocity

- Height above ground

- Meteorological Data:

- Wind speed and direction (hourly or site-specific)

- Ambient temperature, pressure

- Stability class (A–F)

- Mixing height

- Terrain & Topography:

- Land use data (urban/rural classification)

- Elevation and obstacles (buildings, hills)

- Receptor Locations:

- Plant boundary, population centers, schools, water bodies, etc.

- Chemical Properties:

- Boiling point, density, reactivity, IDLH/ERPG/AEGL limits

📜 Regulatory Standards and Guidelines

Air dispersion studies are governed by several national and international regulations. Some key references include:

🏛 Indian Regulations:

- CPCB Guidelines (Central Pollution Control Board)

- MoEFCC requirements for EIA reports

- OISD-150, OISD-118 – Safety guidelines for layout and dispersion

🌐 International Standards:

- USEPA – AERMOD and CALPUFF guidance

- Environment Canada – SCREEN3

- European Environment Agency (EEA) – EMEP/EEA Air Pollutant Emission Inventory Guidebook

- API RP 752/753 – Human exposure risk zones

✅ Refer to our post: List of Codes & Standards for Process Safety

💻 Software Used in Air Dispersion Studies

| Software | Use Case |

|---|---|

| PHAST | Toxic, flammable dispersion from process units |

| AERMOD | Regulatory dispersion for routine emissions |

| CALPUFF | Long-range, non-steady-state modeling |

| SCREEN3 | Preliminary screening |

| FLACS | Explosion and toxic dispersion |

| Fire Dynamics Simulator (FDS) | Smoke and fire plume dispersion |

| GMS/SLAIR | GIS-integrated dispersion over terrain |

📌 Learn more: PHAST Software for Process Safety

🔍 Types of Dispersion Models

1. Gaussian Plume Models

- Most commonly used for continuous emissions

- Assumes steady-state conditions

- Eg: AERMOD, SCREEN3

2. Lagrangian Models

- Tracks the movement of pollutant parcels over time

- Eg: CALPUFF

3. Computational Fluid Dynamics (CFD) Models

- Used for complex terrain or confined areas

- Eg: FLACS, ANSYS Fluent

4. Dense Gas Models

- For heavy gases like chlorine, LPG, ammonia

- Eg: PHAST, SLAB

📐 Methodology for Air Dispersion Studies

Step 1: Define Objectives

- Is it for compliance, risk analysis, or emergency planning?

Step 2: Collect Data

- Source term details

- Meteorological station or modeled met data

- Terrain map (GIS layer if needed)

Step 3: Select Software & Model

- Use AERMOD for compliance, PHAST for toxic dispersion, CFD for detailed plant layouts.

Step 4: Model Setup

- Source configuration

- Receptor grid definition

- Simulation period (worst-case hour/year)

Step 5: Run Simulations

- Generate plume plots, time series, and concentration contours

Step 6: Compare with Exposure Guidelines

- ERPG, AEGL, TLV, IDLH values

Step 7: Report Findings

- Impact zones

- Recommendations for control or design changes

- Regulatory compliance statement

🧪 Case Study: LPG Leak Dispersion from Storage Bullet

Scenario: 10-tonne LPG leak from storage bullet via 25mm hole due to flange failure

- Source Term: 25 mm hole, 10 bar, 40°C

- Release Duration: 3 minutes

- Model Used: PHAST

- Results:

- 1% LFL Zone: 125 m radius

- 10 ppm Toxic Threshold (ERPG-1): 700 m

- Recommendations: Increase fencing, install H₂S detectors, add high-mounted water sprays

✅ Best Practices in Air Dispersion Modeling

- Use site-specific met data for more accuracy.

- Include sensitivity analysis to capture worst-case and average-case dispersion.

- Validate models with field data if available.

- Incorporate building downwash for stacks near tall structures.

- Document all assumptions in the final report.

- Include seasonal wind roses for annual impact analysis.

⚠️ Common Pitfalls to Avoid

- Using default meteorological profiles without validation

- Ignoring dense gas behavior in heavy gas releases

- Skipping terrain effects in hilly regions

- Not including critical receptors like schools or rivers

- Over-reliance on Gaussian models in complex geometries

❓ FAQs

Q1: Is air dispersion modeling mandatory for all process plants?

Yes, especially for new projects undergoing EIA or those storing hazardous materials under MSIHC rules.

Q2: Which model is best for accidental toxic gas release?

PHAST, SLAB, and FLACS are preferred for toxic dispersion modeling.

Q3: What is the difference between AERMOD and CALPUFF?

AERMOD is a steady-state Gaussian model used for short-range modeling; CALPUFF is non-steady-state and used for long-range, time-varying scenarios.

🔚 Conclusion

Air dispersion studies are a vital tool in the arsenal of environmental and process safety engineers. From safeguarding communities to optimizing stack heights, dispersion modeling ensures that industrial operations remain compliant, sustainable, and safe. With increasing regulatory scrutiny, the importance of accurate, well-documented studies cannot be overstated.

Start small with SCREEN3, and as your project complexity grows, migrate to more advanced tools like AERMOD, CALPUFF, or PHAST. When in doubt, consult a qualified dispersion modeling consultant.