Control of Major Accident Hazards (COMAH) – A Complete Guide for High-Hazard Industries

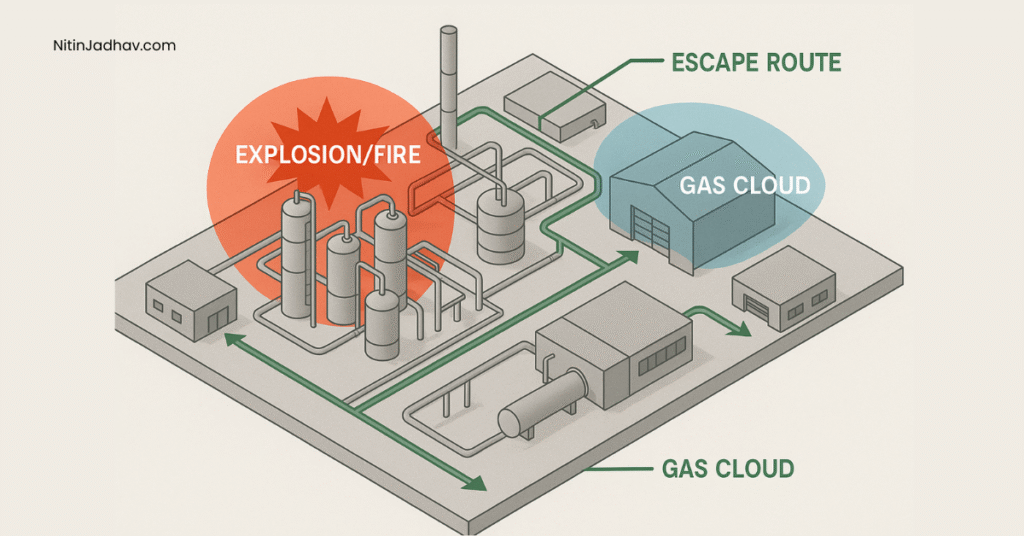

Fire Protection, Industrial Compliance, Industrial Safety, Process Safety, Risk AssessmentA comprehensive guide to COMAH (Control of Major Accident Hazards) covering its objectives, tier classification, risk assessments, safety management systems, emergency planning, and global equivalents for high-hazard industries.

Control of Major Accident Hazards (COMAH) – A Complete Guide for High-Hazard Industries Read Post »