🔍 Introduction

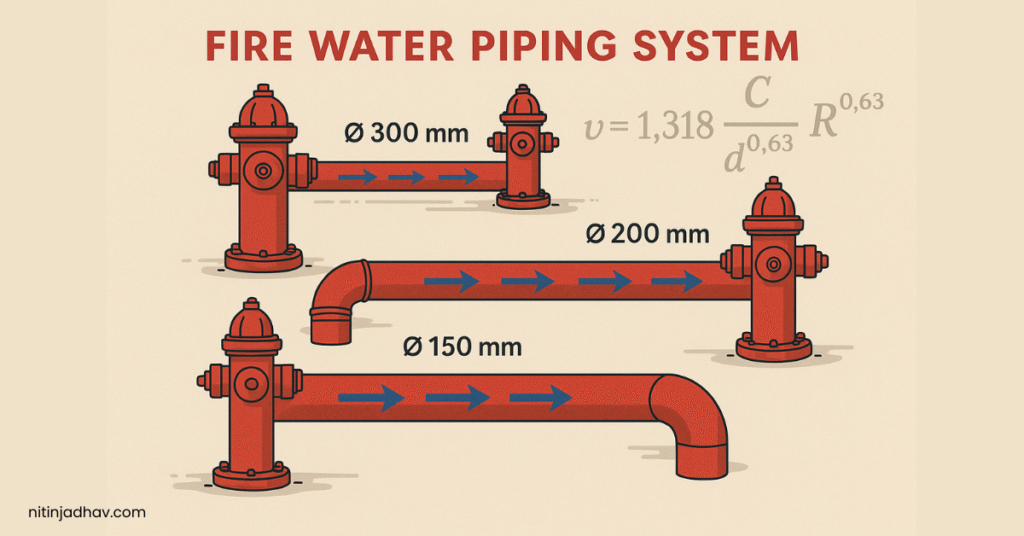

In fire protection systems, pipe sizing is a critical design step that ensures water is delivered at the required flow and pressure during an emergency. Whether you’re working on a hydrant system, sprinkler network, or foam-based protection line, selecting the right pipe size is essential for both compliance and performance.

In this article, you’ll learn:

- Why pipe sizing matters in fire water systems

- The standard formula for pipe diameter

- Reference flow velocities as per NFPA/OISD

- Manual calculation with example

- Use of a free online calculator

- FAQs for on-site engineers

🧠 Why Accurate Pipe Sizing Matters

Improper sizing can lead to:

- Insufficient flow or pressure at hydrants/nozzles

- Excessive pressure drop over long distances

- Higher capital and operating costs

- Non-compliance with NFPA, OISD, or IS fire codes

Correct pipe sizing ensures:

✅ Reliable flow during a fire emergency

✅ Minimal friction loss

✅ Lower chance of erosion or noise

✅ Cost-effective system design

📐 Formula for Pipe Size Calculation

The basic formula used in hydraulics to find pipe diameter is: Q=A×VQ = A \times VQ=A×V A=QV⇒D=4QπVA = \frac{Q}{V} \quad \Rightarrow \quad D = \sqrt{\frac{4Q}{\pi V}}A=VQ⇒D=πV4Q

Where:

- Q = Flow rate (m³/s)

- V = Flow velocity (m/s)

- D = Internal pipe diameter (m)

- A = Cross-sectional area (m²)

⚖️ Standard Velocity Guidelines (NFPA / OISD)

| Pipe Type | Recommended Velocity |

|---|---|

| Hydrant Lines | 3.0 – 5.0 m/s |

| Sprinkler Mains | 2.0 – 3.0 m/s |

| Foam Lines | Max. 5.0 m/s |

| Pump Suction Lines | 1.5 – 2.5 m/s |

🔎 Tip: Keep friction losses below 1 bar/km to avoid performance loss over long distances.

🧮 Manual Example: Pipe Size for Hydrant Line

Given:

- Flow Rate = 720 m³/hr

- Velocity = 3.5 m/s

Step 1: Convert flow rate to m³/s Q=7203600=0.2 m³/sQ = \frac{720}{3600} = 0.2 \, \text{m³/s}Q=3600720=0.2m³/s

Step 2: Calculate Diameter D=4×0.2π×3.5≈0.27 m=270 mmD = \sqrt{\frac{4 \times 0.2}{\pi \times 3.5}} \approx 0.27 \, \text{m} = 270 \, \text{mm}D=π×3.54×0.2≈0.27m=270mm

Answer: Use 300 NB commercial pipe

🔧 Use Our Fire Water Pipe Size Calculator (Instant)

To automate the above calculation, use our free online calculator below:

👉 Adjust the flow rate and velocity values to get accurate pipe diameter and area instantly.

Pipe Flow Calculator

Enter Velocity and Flow Rate to see pipe details

| Cross-Sectional Area | 0.00 mm² |

| Pipe Diameter (mm) | 0.00 mm |

| Pipe Diameter (in) | 0.00 in |

📏 Pipe Size Reference Table (NB vs Diameter)

| Nominal Bore (NB) | Approx. ID (mm) | Cross-Section Area (mm²) |

|---|---|---|

| 100 NB | ~102 mm | 8,171 mm² |

| 150 NB | ~154 mm | 18,602 mm² |

| 200 NB | ~202 mm | 32,042 mm² |

| 250 NB | ~254 mm | 50,686 mm² |

| 300 NB | ~303 mm | 72,105 mm² |

| 350 NB | ~353 mm | 97,870 mm² |

🛠️ Engineering Tips for Pipe Sizing

- Use internal diameter in formulas, not outer diameter

- Keep water velocity below 5 m/s in carbon steel pipes

- For large networks, simulate using software like PipeFlow Expert, WaterGEMS, or AutoPIPE

- Always cross-check with design codes: OISD-117, NFPA-24, IS 3034

❓ FAQs – Pipe Size Calculation

Q1: What’s the maximum allowed velocity in fire lines?

Ideally, < 5.0 m/s to avoid erosion and pressure spikes.

Q2: How do I convert pipe size from mm to inches?

Use the calculator. Divide mm by 25.4 to get inches.

Q3: Should I consider friction loss while sizing?

Yes. Use Darcy-Weisbach or Hazen-Williams method to validate head loss.

Q4: Can I use 100 NB pipe for hydrant?

No. Minimum standard for hydrant loop is 150 NB, preferably 200 NB.