🔍 What is Escape, Evacuation, and Rescue Analysis (EERA)?

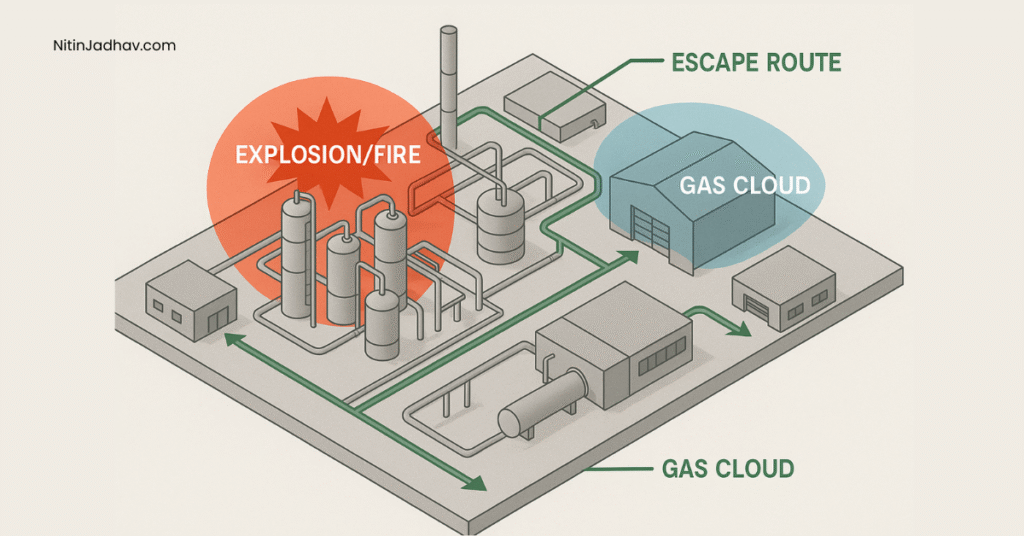

EERA (Escape, Evacuation, and Rescue Analysis) is a systematic safety study that evaluates whether personnel in a facility can safely escape from immediate danger, evacuate the premises, and be rescued if necessary, in the event of major accident scenarios such as fire, explosion, or toxic gas release.

It is a critical part of risk assessment, layout design, and safety case development, especially in high-risk facilities like:

- Oil & Gas Installations

- Offshore Platforms

- LNG Terminals

- Refineries

- Petrochemical Plants

- Fertilizer & Chemical Units

👉 Related Reading: Process Safety Management – Golden Rules

✅ Objectives of EERA

- Ensure safe evacuation routes and rescue facilities exist for all personnel

- Identify gaps in escape provisions during credible worst-case events

- Comply with regulatory and international safety standards

- Enhance layout design and emergency preparedness

🧭 Key Components of EERA

- Escape – Moving to a safer area immediately after recognizing a hazard

- Evacuation – Leaving the facility or area systematically and safely

- Rescue – Helping trapped or injured personnel reach safety using trained teams

📌 Detailed Methodology for EERA

1. Define Scope

- Facility type (onshore/offshore)

- Number and type of occupants (permanent/temporary)

- Areas of analysis (control room, maintenance bay, utility blocks, etc.)

2. Data Collection

- Updated plot plan, layout, and P&IDs

- Occupancy schedule

- Details of emergency systems: PA, alarms, F&G detectors

- Fire and explosion modeling results (PHAST/FRED)

- QRA output for hazard zones and fatality contours

👉 Try our: QRA Basics Guide

3. Identify Major Accident Hazards (MAHs)

Use hazard studies like:

- HAZID

- HAZOP

- QRA

Common scenarios:

- Jet fire from pipe rupture

- BLEVE near process area

- Toxic gas cloud from ammonia or chlorine release

- Explosion impacting occupied buildings

4. Map Escape Routes and Assembly Areas

- Identify primary and secondary escape routes

- Locate muster points and shelter-in-place (SIP) areas

- Evaluate route distances, widths, lighting, and visibility

📍 Tip: Maintain max 400 m distance from farthest location to safe zone

5. Time-to-Escape Calculation

Calculate:

- TET (Total Evacuation Time) = detection + response + travel time

- ASET (Available Safe Egress Time) = time before route becomes unsafe

✅ Ensure:

TET < ASET for all personnel in all hazard scenarios

6. Survivability and Accessibility Check

Evaluate escape path exposure to:

- Thermal radiation (>4.7 kW/m² unsafe)

- Overpressure (>0.3 bar dangerous for unreinforced structures)

- Visibility due to smoke or gas

- Collapsed structures or blast debris

Use modeling tools like:

- PHAST

- CFD tools (FLACS, Fire Dynamics Simulator)

- Evacuation simulation software (Pathfinder)

7. Rescue Provisions Review

- Dedicated rescue teams available 24/7

- Breathing apparatus, stretchers, flameproof suits

- Accessibility for ambulances, helipads (for offshore), rescue boats

- Rescue response drills and mock evaluations

8. Risk Ranking & Recommendations

- Identify high-risk zones

- Recommend:

- New escape ladders/stairs

- Improved signage & lighting

- PA system coverage extension

- Structural protection (fireproofing)

- Relocation of muster points or control room

9. Documentation

Prepare an EERA Report including:

- Facility overview

- Hazard scenarios

- Escape route plans

- TET vs ASET comparisons

- Rescue plan

- Improvement recommendations

📚 Applicable Standards & Guidelines

| Code/Standard | Description |

|---|---|

| OISD-STD-116 | Safety in Petroleum Installations |

| ISO 15544 | Emergency Response Planning |

| OSHA 1910.38 | Emergency Action Plans |

| API RP 752 / 753 | Siting of Occupied Buildings |

| DNV-RP-E401 | Offshore EERA Guidelines |

| NFPA 101 | Life Safety Code |

🔐 Best Practices

- EERA should be done during design and operation phase

- Reassess EERA after layout or occupancy change

- Integrate EERA findings with fire & gas detection and PA/GA system

- Conduct regular evacuation drills with mock fire/toxic release events

- Collaborate with rescue authorities and first responders

🧠 Conclusion

In the world of high-risk industrial operations, Escape, Evacuation, and Rescue Analysis (EERA) is not optional—it’s life-critical. It protects people, minimizes casualties, and ensures a safe work environment. A well-conducted EERA is a proactive safety investment and a strong compliance measure.