🔍 Introduction

In modern process industries, ensuring safety goes beyond identifying hazards — it involves quantifying risk and applying the right protection measures. Two commonly used tools in the safety lifecycle are SIL (Safety Integrity Level) and LOPA (Layer of Protection Analysis).

While often used together, SIL and LOPA serve different purposes and are applied at different stages of risk evaluation. Misunderstanding their roles can lead to overdesign, under-protection, or even regulatory non-compliance.

This article explores SIL vs LOPA in detail — definitions, methodology, differences, similarities, real-world examples, and when to use each. Ideal for process safety engineers, control system designers, and HSE professionals.

✅ What is SIL (Safety Integrity Level)?

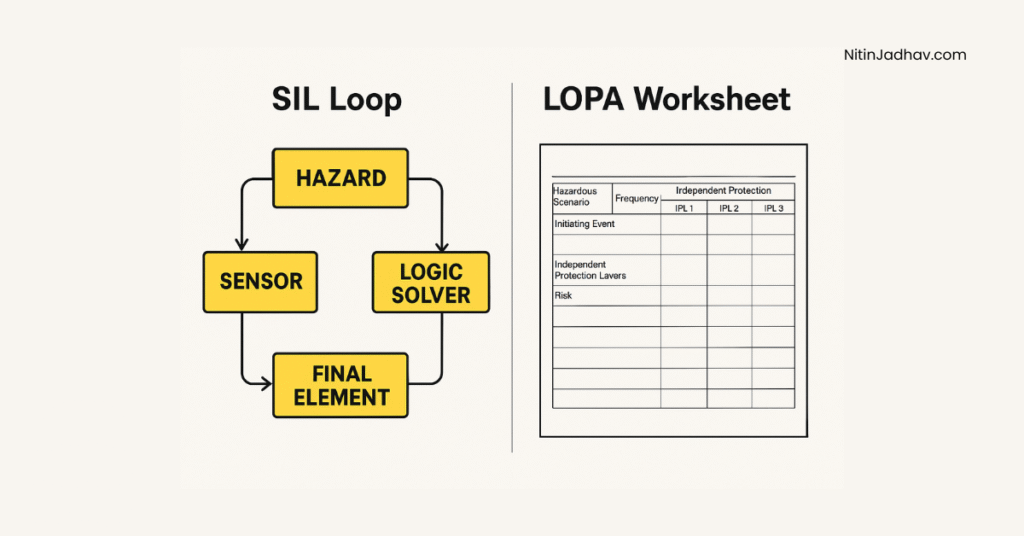

SIL is a measure of the reliability and performance of a Safety Instrumented Function (SIF). It quantifies how likely a SIF will successfully perform its task when demanded.

SIL ratings are defined by IEC 61508/IEC 61511 and are categorized into 4 levels:

- SIL 1: Least stringent (e.g., general process controls)

- SIL 2–3: Moderate to high risk applications (e.g., reactor shutdown, flare systems)

- SIL 4: Extremely critical systems (rare in industrial practice)

🎯 SIL Key Parameters:

- PFDavg (Probability of Failure on Demand)

- SIF Architecture (1oo1, 1oo2, 2oo3)

- Test interval & diagnostic coverage

- SRS (Safety Requirements Specification) documentation

📌 SIL Application Example:

A high-pressure separator is protected by a pressure transmitter + shutdown valve. If the analysis determines that the consequence of failure is severe and the likelihood is high, a SIL 2 level may be assigned to the SIF.

Explore: What is QRA – Quantitative Risk Assessment

✅ What is LOPA (Layer of Protection Analysis)?

LOPA is a semi-quantitative risk analysis technique used to evaluate whether existing protection layers are sufficient to meet acceptable risk levels.

LOPA bridges the gap between HAZOP and SIL assignment. It is less complex than QRA, but more rigorous than qualitative HAZOP.

🔍 Key Concepts in LOPA:

- Initiating Event Frequency (IEF)

- Independent Protection Layers (IPLs)

- Risk Reduction Factor (RRF)

- Target Risk Tolerability

LOPA calculates how many IPLs (such as alarms, interlocks, relief valves) are required to reduce the risk to acceptable levels. If IPLs are not enough, a SIF with a SIL rating is introduced.

📌 LOPA Application Example:

During a HAZOP, a scenario is identified where vessel overpressure may occur due to valve failure. LOPA determines that two IPLs exist (alarm + PSV), but these aren’t sufficient. Hence, a SIL 1 shutdown loop is recommended.

Explore: List of Process Safety Studies

🔁 SIL vs LOPA – Key Differences

To clarify their distinct roles, here’s a breakdown of how SIL and LOPA differ across key dimensions:

| Feature | SIL (Safety Integrity Level) | LOPA (Layer of Protection Analysis) |

|---|---|---|

| Purpose | Determines the reliability level required for a Safety Instrumented Function (SIF) | Assesses whether a SIF is required by analyzing risk gaps |

| Nature | Fully quantitative, based on statistical failure data | Semi-quantitative, based on frequency and consequence estimation |

| Focus | How well a protection function must perform (PFDavg) | Whether existing protection layers are sufficient |

| Timing | Applied after risk has been deemed intolerable by LOPA or QRA | Applied after HAZOP, before SIL analysis |

| Outputs | SIL level (1 to 4), PFDavg, SRS documentation | Risk Reduction Factor (RRF), IPL adequacy, recommendation for SIL |

| Tools Used | exSILentia, PFD calculators, SIL verification tools | LOPA worksheets, risk matrices, IPL databases |

| Applicable Standards | IEC 61508, IEC 61511 | CCPS LOPA Book, IEC 61511 |

👉 In simple terms:

- LOPA asks: Do we need an additional layer of protection?

- SIL defines: How reliable should that protection be?

🤝 SIL and LOPA – How They Work Together

LOPA helps determine if a SIF is required, and what level of SIL is needed. It’s a practical tool to justify whether existing IPLs are enough.

Once LOPA concludes that risk is not tolerable, SIL assignment ensures the new SIF has the appropriate reliability to close the risk gap.

🔗 Think of LOPA as “Do we need a SIF?” and SIL as “How strong should the SIF be?”

Explore: Fire and Gas Detection Philosophy

🛠 Tools & Documentation

- LOPA Worksheets (event, consequence, IPL, RRF)

- SRS (Safety Requirement Specification)

- PFD calculations for instrumentation loops

- SIL Verification Tools (ex: exSILentia, TÜV tool)

📚 Regulatory & Industry References

- IEC 61508 & 61511 – Functional safety standards

- CCPS Guidelines for LOPA

- API 754 – Process Safety Metrics

- OISD Guidelines (India-specific)

🧠 Real-World Example

📍 Case Study: Gas Compressor Shutdown Loop

- HAZOP identified overpressure due to cooling failure

- LOPA calculated RRF of 100 needed to reduce risk

- Two IPLs provided RRF of only 10

- SIF added with SIL 2 rating (PFDavg = 1×10⁻³)

- Verified using SIL tool and documented in SRS

Outcome: Acceptable risk achieved and documented traceability ensured

❓ FAQs

Q1: Is LOPA mandatory before SIL assignment?

A: In most best practices and company standards, yes. LOPA validates the need for SIL.

Q2: Can a loop be assigned SIL directly from HAZOP?

A: Not recommended. SIL must follow risk gap analysis (via LOPA or QRA).

Q3: Is SIL 4 used in industry?

A: Rarely. Most SIFs fall under SIL 1–3. SIL 4 is cost-prohibitive and used in nuclear/military.

Q4: Is LOPA a replacement for QRA?

A: No. QRA gives full risk profile; LOPA is simpler and used for specific scenarios.

✅ Summary

SIL and LOPA are both essential tools in a process safety engineer’s toolbox. While LOPA determines whether a SIF is required, SIL ensures that the SIF meets the reliability required to mitigate that risk.

✅ Use LOPA to decide “if” and SIL to define “how well.”

Together, they build a strong, auditable, and cost-effective safety framework.