Introduction

Industrial environments like oil & gas, petrochemical, chemical manufacturing, and pharmaceuticals often handle flammable gases, vapors, and dusts. If these materials leak or accumulate in the presence of an ignition source, they can cause fires, explosions, or flash fires. This risk is addressed through a critical process called Hazardous Area Classification (HAC).

Hazardous Area Classification is a technique used to analyze and categorize areas where explosive gas or dust atmospheres may form. It helps ensure the safe selection, design, and installation of electrical and non-electrical equipment in these areas.

This comprehensive guide covers:

- What is HAC

- Applicable standards

- Zone classification

- Equipment selection

- Documentation requirements

- Case studies and industry best practices

👉 Internal Link: Codes and Standards for Process Safety and Loss Prevention

What is Hazardous Area Classification?

Hazardous Area Classification (HAC) is the process of identifying areas where explosive atmospheres may be present due to the presence of flammable gases, vapors, or dust. These areas are then categorized into zones based on the frequency and duration of the occurrence.

The goal of HAC is to:

- Reduce the risk of ignition and explosion

- Ensure safety of personnel and assets

- Comply with local and international regulations

- Guide the selection of explosion-proof equipment

Why is Hazardous Area Classification Important?

- Prevents fire and explosion risks in high-hazard industries

- Enables the use of appropriate Ex-rated equipment

- Supports compliance with OISD, IEC, NFPA, ATEX, NEC, IS standards

- Enhances design of ventilation, electrical isolation, and access control

- Forms the basis for equipment certification, maintenance, and inspections

Key Components of HAC

| Component | Description |

|---|---|

| Flammable substance | Type of gas, vapor, or dust |

| Ignition source | Sparks, heat, friction, static electricity |

| Ventilation rate | Natural or forced |

| Area zoning | Based on frequency and duration |

| Equipment classification | Explosion-proof rating and protection level |

Governing Standards and Regulations

| Standard | Region | Focus |

|---|---|---|

| IEC 60079 Series | Global | Equipment and area classification |

| NEC Article 500–505 | USA | Zone and Division classification |

| ATEX Directive 99/92/EC | Europe | Workplace and equipment requirements |

| IS/IEC 60079 | India | Based on IEC, adopted by BIS |

| OISD-STD-113 | India | Area classification for oil & gas |

| NFPA 497 / 499 | USA | Classification of flammable vapors and dust |

👉 Internal Link: List of Indian and International Standards for Fire and Explosion Protection

How Hazardous Areas are Classified

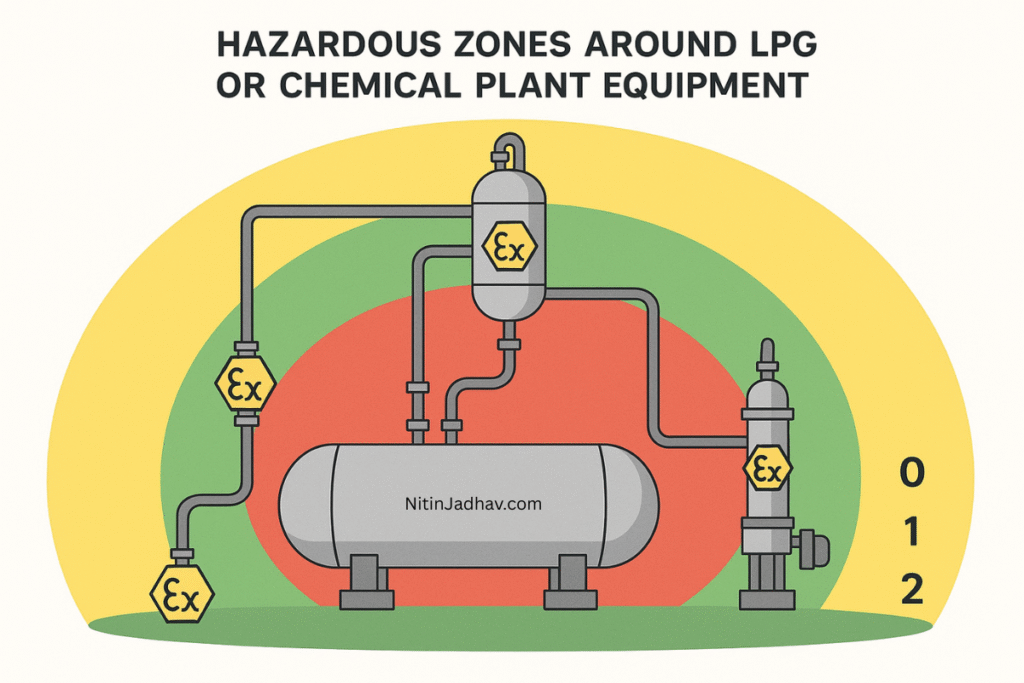

Hazardous areas are classified into zones based on how often and how long an explosive atmosphere is present.

For Gases and Vapors:

| Zone | Description |

|---|---|

| Zone 0 | Explosive atmosphere present continuously or for long periods (e.g., inside process vessels) |

| Zone 1 | Likely to occur during normal operation (e.g., pump seals, sampling points) |

| Zone 2 | Unlikely to occur or only for short periods (e.g., well-ventilated open areas) |

For Combustible Dust:

| Zone | Description |

|---|---|

| Zone 20 | Explosive dust atmosphere always present |

| Zone 21 | Likely to occur during normal operations |

| Zone 22 | Rarely occurs and only briefly |

Typical Sources of Flammable Atmospheres

- LPG/LNG pumps and storage tanks

- Compressor suction and discharge flanges

- Valve glands, pump seals

- Tank venting systems

- Loading/unloading bays

- Filter/dryer discharges

- Bagging areas (for dust)

Factors Affecting Area Classification

- Properties of the substance (flash point, LEL, auto-ignition temperature)

- Process pressure and temperature

- Leak size and frequency

- Ventilation (natural or mechanical)

- Enclosure or open area

- Weather conditions and air movement

Equipment Selection Based on Hazardous Area Classification

Equipment used in hazardous areas must be certified and labeled for use in the appropriate zone.

Equipment Protection Levels (EPL)

| EPL | Applicable Zone | Risk Level |

|---|---|---|

| Ga / Da | Zone 0 / Zone 20 | Very high |

| Gb / Db | Zone 1 / Zone 21 | High |

| Gc / Dc | Zone 2 / Zone 22 | Normal |

Types of Protection

| Protection | Code | Description |

|---|---|---|

| Flameproof | Ex d | Contains explosion inside enclosure |

| Increased Safety | Ex e | No arcs/sparks during normal operation |

| Intrinsic Safety | Ex i | Limits energy below ignition level |

| Pressurized | Ex p | Positive pressure inside enclosure |

| Encapsulation | Ex m | Seals ignition-capable parts |

| Non-sparking | Ex n | Designed to not spark under normal use |

👉 Internal Link: Fire Protection Systems and Equipment Selection Guide

Sample Hazardous Area Classification Table

| Equipment | Location | Gas Group | Zone | Equipment Type |

|---|---|---|---|---|

| Centrifugal Pump | LPG Area | IIA | Zone 1 | Ex d IIA T3 |

| Tank Roof | Floating Roof | IIB | Zone 0 | Ex ia IIB T4 |

| Control Room | Outside Fence | – | Safe Area | Non-Ex Equipment |

Sample Hazardous Area Classification Drawing

A good HAC study includes:

- Plan views and elevations of process areas

- Zone boundaries marked clearly (color-coded)

- Legend for gas group, temperature class, EPL

- Equipment IDs with Ex certification

These are essential for:

- Installation planning

- Electrical equipment procurement

- Construction audits

- Fire & Gas Mapping

👉 Internal Link: Fire and Gas Detector Mapping Study

Tools and Software Used in HAC Studies

| Tool | Use |

|---|---|

| AutoCAD | Plot plans and 2D zoning layout |

| SmartPlant Electrical | Electrical component classification |

| DIAL Zone Drawing Tool | HAC visualization |

| FLACS / PHAST | Gas dispersion modeling for zone validation |

Key Outputs of an HAC Study

- Hazardous Area Classification Report

- HAC Layout Drawings

- Equipment Lists with Zone Tagging

- Ventilation Assessment (where required)

- Recommendations for zoning optimization

Indian Industry Perspective

In India, area classification is mandated by:

- OISD 113 for refineries and oil terminals

- PESO for LPG, LNG, and POL installations

- Factories Act & Rules for hazardous processes

Common mistakes include:

- Treating open plant areas as non-hazardous

- Not considering dust in bagging zones

- Using uncertified electrical components

Best Practices in HAC

- Use up-to-date P&IDs, process data, and MSDS sheets

- Collaborate with operations and maintenance teams

- Validate zones using dispersion modeling (PHAST or CFD)

- Label zone areas physically (Zone 1 / Zone 2 signs)

- Use standard color codes in drawings

- Review HAC periodically (especially after MOC)

Case Study: LPG Bottling Plant

Scenario: HAC performed for a new LPG filling plant

Findings:

- Zone 0 inside pump seal and tank roof manholes

- Zone 1 within 1.5 m around pumps and valves

- Zone 2 up to 3 m in ventilated corridors

Recommendations: - All motors and panels in Zone 1 rated Ex d IIA T3

- Lighting in Zone 2 specified with Ex n rating

- Updated zoning drawings shared with PESO

Outcome: PESO approval received; safety optimized without over-specification.

FAQs

Q1: What is the difference between Zone 1 and Zone 2?

Zone 1 is where explosive atmospheres are likely during normal operation; Zone 2 is unlikely, and if occurs, lasts for a short duration.

Q2: Are dust and gas zones the same?

No. Dust zones are Zone 20, 21, 22 and follow different material characteristics (combustibility, dust cloud formation).

Q3: Is HAC a one-time study?

No. It must be reviewed after plant modifications, incidents, or every 5 years as part of PSM.

Q4: Can I use non-Ex equipment in Zone 2?

Only if it’s certified as Ex n or suitable for that zone. Regular non-certified equipment is prohibited.

Conclusion

Hazardous Area Classification is not just a design deliverable—it’s a life-saving safety analysis that underpins how you choose, install, and maintain equipment in flammable or explosive atmospheres.

A well-executed HAC study enables safe plant operation, cost-effective equipment selection, and compliance with national and international safety standards. Whether you’re planning a new project or upgrading an old facility, integrating HAC into the design and operational workflow is non-negotiable for any process safety program.