Introduction

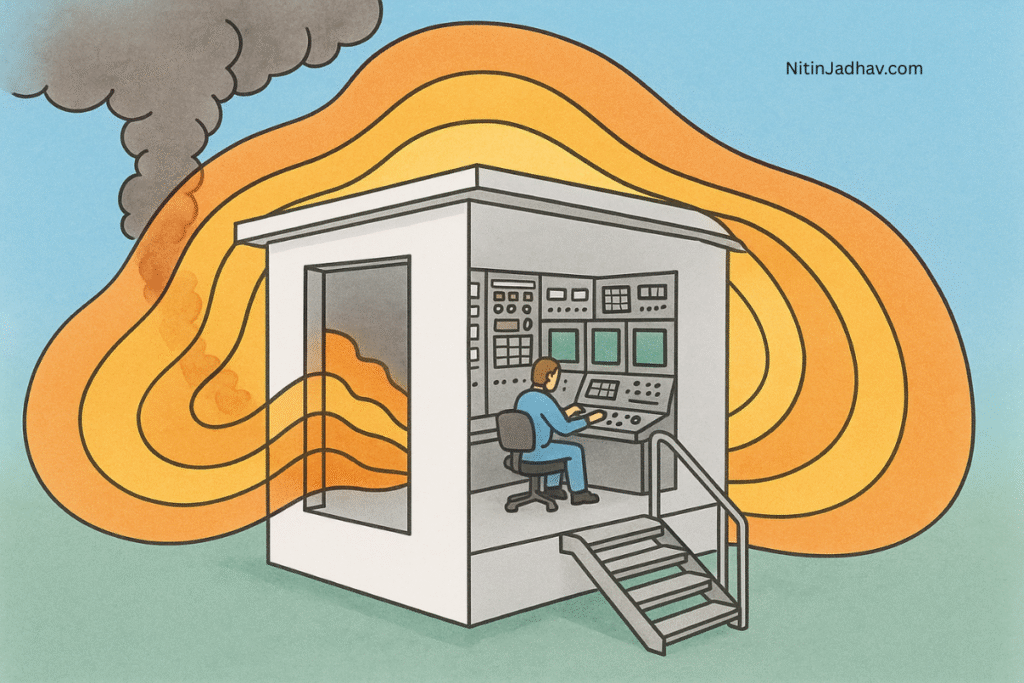

In high-hazard process industries such as oil & gas, petrochemicals, and chemical manufacturing, controlling and managing the risk of smoke and toxic gas ingress into buildings is essential. A Smoke and Gas Ingress Study is a specialized risk assessment that evaluates the potential for hazardous substances (smoke, toxic vapors, or flammable gases) to enter occupied or critical buildings during abnormal events such as leaks, fires, or explosions.

This guide outlines the complete methodology, dispersion calculations, impact assessment, regulatory compliance, and mitigation strategies associated with smoke and gas ingress studies. It is designed for HSE professionals, process safety engineers, and risk consultants.

Objectives of the Study

- Assess potential ingress of hazardous smoke and gas into control rooms, sub-stations, analyzer shelters, MCC rooms, or other buildings

- Perform dispersion modeling to estimate concentration levels at the building boundary

- Evaluate the impairment of critical safety functions or building operations

- Determine the impact on personnel health and survivability

- Recommend engineering and administrative controls to mitigate ingress risks

Why is Smoke and Gas Ingress Important?

1. Personnel Safety

Inhalation of smoke or toxic gases such as H2S, CO, or ammonia can be fatal or cause long-term health issues.

2. Control Room Integrity

If flammable gases enter control or electrical rooms, it could lead to explosions, fires, or control system shutdown.

3. Compliance Requirements

International safety regulations like API RP 752/753, IEC 60079, and OISD standards mandate the evaluation of building vulnerability to external gas release or fire events.

Buildings Considered in the Study

- Control Rooms

- Substations

- Analyzer Shelters

- Laboratory Buildings

- Field Auxiliary Rooms (FARs)

- Remote Instrument Enclosures

- Fire and Gas (F&G) Cabinets

Key Definitions

- Ingress: Entry or seepage of gas or smoke into an enclosed space through gaps, ventilation, or penetrations

- Toxic Load: Accumulated exposure concentration (ppm) over time that impacts human health

- Lower Explosive Limit (LEL): Minimum concentration of flammable gas in air required to form a combustible mixture

Methodology of Smoke and Gas Ingress Study

Step 1: Identify Potential Release Scenarios

- Inventory of hazardous chemicals (Toxic, Flammable)

- Leak frequencies and release quantities (e.g., via Failure Rate Data)

- Scenarios include:

- Flange leaks

- Pipeline rupture

- PSV discharges

- Storage tank overfill

- Fire smoke from adjacent unit

Step 2: Dispersion Modeling

- Use dispersion modeling software such as PHAST, FLACS, or AERMOD

- Input parameters:

- Release height and direction

- Wind speed and direction (use site met data)

- Temperature, pressure, humidity

- Building coordinates and geometry

Output

- Gas or smoke concentration at the building boundary in ppm or %LEL

- Isopleth maps showing dispersion pattern

- Concentration vs. time graphs

Step 3: Ingress Analysis

- Building Air Infiltration Rate (AER)

- HVAC system specifications (pressurization, recirculation, fresh air intake location)

- Crack flow or leakage rate estimation through:

- Door gaps

- Cable gland penetrations

- Poor sealing

Equation

Cin(t)=QV(Cout−Cin(t))C_{in}(t) = \frac{Q}{V}(C_{out} – C_{in}(t))

Where:

- Cin(t)C_{in}(t): Concentration inside building

- CoutC_{out}: Concentration outside (from dispersion model)

- QQ: Air exchange rate

- VV: Volume of building

Impact Assessment

1. Human Impact

- Use AEGL (Acute Exposure Guideline Levels) and IDLH (Immediately Dangerous to Life or Health) levels to compare:

- Eye irritation

- Dizziness

- Respiratory failure

| Gas | AEGL-1 (ppm) | AEGL-2 (ppm) | AEGL-3 (ppm) |

|---|---|---|---|

| H2S | 0.2 | 27 | 76 |

| Ammonia | 30 | 220 | 2700 |

| Carbon Monoxide | 200 | 880 | 1700 |

2. Functional Impact

- Evaluate risk to:

- Electrical equipment due to explosive gas ingress

- Emergency shutdown systems

- Fire detection systems

- Process control rooms (loss of monitoring)

3. Structural Impact

- Smoke accumulation in unventilated areas can lead to:

- Visibility loss

- Equipment overheating

- Cable insulation degradation

Regulatory Framework

- API RP 752: Management of Hazards Associated with Location of Process Plant Buildings

- API RP 753: Siting of Portable Buildings

- OISD-STD-116: Control Room Design

- NFPA 92/101: Smoke Control and Life Safety Codes

- IEC 60079-10: Classification of Hazardous Areas

Mitigation Measures

Engineering Controls

- HVAC pressurization with airlock entry

- Toxic and flammable gas detectors at air intakes

- Smoke extraction systems

- Gas-tight sealing of cable glands and ductwork

- Fire-resistant and explosion-proof building materials

Administrative Controls

- Shutdown procedures for HVAC during release

- Emergency response plans for smoke/gas ingress

- Building access restrictions during plume incidents

- Use of SCBAs and portable gas monitors

Redundancy Options

- Dual HVAC units with positive pressure control

- Fire/gas detection linked to automatic dampers

- Secondary shelters (blast resistant) for critical personnel

Tools & Software for Ingress Studies

| Tool | Purpose |

|---|---|

| PHAST | Dispersion & smoke modeling |

| FLACS | 3D CFD simulation (gas/smoke) |

| AERMOD | Atmospheric dispersion modeling |

| CONTAM | Indoor air quality and infiltration analysis |

| EXTOXNET | Toxic exposure level referencing |

Case Study: Gas Ingress into Analyzer Shelter

Scenario:

- H2S leak from flange 20m away

- Wind speed: 3 m/s; Release rate: 0.05 kg/s

- Shelter volume: 45 m³

- Air leakage rate: 0.2 m³/min

Result:

- PHAST shows 100 ppm H2S at shelter door

- Ingress model calculates 25 ppm inside after 3 minutes

- AEGL-2 exceeded → Immediate evacuation needed

Recommendations:

- Install gas detector at air intake

- Seal base of door with weather stripping

- Pressurize shelter with filtered air

Integration with Other Safety Studies

- HAZID: Identify gas release sources

- QRA: Estimate frequency and consequence

- EERA: Smoke ingress into evacuation routes

- COMAH: Demonstrate control of major hazards

- F&G Mapping Study: Validate detector coverage around building

Read related articles:

- Fire and Gas Detector Mapping Study

- Emergency Response and Disaster Management Plan (ERDMP)

- Hazardous Area Classification

Conclusion

A Smoke and Gas Ingress Study plays a pivotal role in safeguarding both personnel and critical infrastructure. By integrating dispersion modeling with building-specific infiltration analysis, the study offers data-driven insights into improving design and operational resilience.

For high-risk industries, implementing these studies is not only a compliance requirement but a proactive step in risk reduction and safety enhancement.

Need Help with Ingress Study?

Our team at NitinJadhav.com offers expert consulting and analysis services to help industries conduct detailed Smoke and Gas Ingress Studies. Reach out to ensure your facilities are protected from invisible hazards.

Stay safe. Stay compliant.