Introduction

High-risk industries such as oil & gas, petrochemicals, energy, and chemicals routinely handle hazardous materials that could lead to major accidents — fires, explosions, or toxic releases with devastating effects. The Control of Major Accident Hazards (COMAH) regulations provide a structured legal and engineering framework to prevent and mitigate such incidents.

Originally implemented in the UK following the Seveso disaster of 1976, COMAH has become a global benchmark for safety regulations. It aims to ensure that operators take all necessary steps to prevent major accidents and limit their consequences for people and the environment.

This article offers a deep dive into COMAH regulations, applicability, safety management systems, risk assessment methodologies, reporting obligations, and industry best practices.

👉 Internal Link: Comprehensive List of Process Safety Studies

What is COMAH?

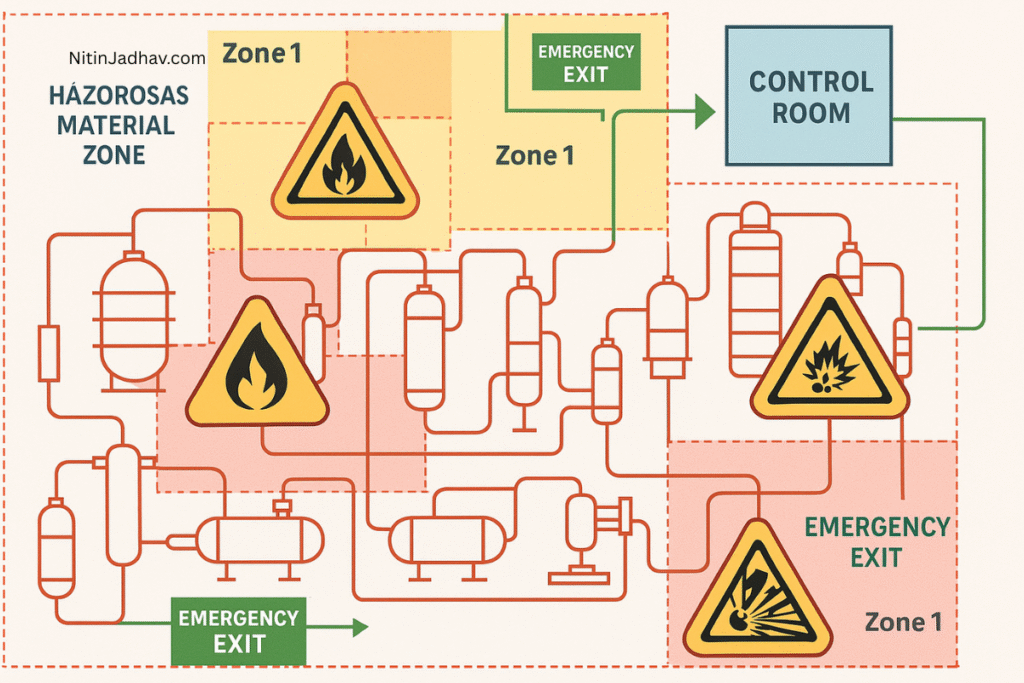

COMAH (Control of Major Accident Hazards) is a regulatory regime that applies to establishments storing or processing dangerous substances above specific threshold quantities. COMAH’s goal is accident prevention and impact minimization.

The regulations require operators to:

- Identify major accident hazards

- Conduct risk assessments

- Implement safety management systems (SMS)

- Prepare on-site and off-site emergency plans

- Report major accidents and near misses

- Maintain a Safety Report (for upper-tier sites)

Origin of COMAH Regulations

| Event | Impact |

|---|---|

| Seveso Disaster, Italy (1976) | Dioxin release from a chemical plant |

| Flixborough Explosion, UK (1974) | Reactor explosion killed 28 workers |

| Bhopal Gas Tragedy, India (1984) | MIC gas release causing >15,000 deaths |

| Piper Alpha, North Sea (1988) | Offshore fire explosion, 167 fatalities |

These disasters prompted the EU to introduce the Seveso Directive, which laid the foundation for COMAH and similar frameworks globally.

COMAH Tier Classification

| Tier | Description | Requirements |

|---|---|---|

| Lower Tier | Facilities with substances > Lower Threshold | Basic risk assessment, safety report not mandatory |

| Upper Tier | Substances > Higher Threshold | Full safety report, ERP, regulator inspections, public disclosure |

👉 Threshold quantities vary by substance as per the COMAH Schedule of Dangerous Substances.

COMAH Objectives

- Prevent major accidents involving dangerous substances

- Limit consequences to people, property, and the environment

- Ensure high standards of safety management

- Promote transparency and public access to safety information

- Create emergency preparedness through coordinated response

Industries Affected by COMAH

- Refineries

- Chemical manufacturing

- LPG terminals

- Fertilizer production

- Explosives and ammunition depots

- Pharmaceutical intermediates

- Food processing plants (with ammonia/cold storage)

👉 Internal Link: FERA Study Guide – Fire & Explosion Risk Assessment

Substances Covered Under COMAH

The COMAH regime categorizes dangerous substances into classes such as:

- Toxic (e.g., Chlorine, MIC, Hydrogen Cyanide)

- Explosive (e.g., Ammonium Nitrate, TNT)

- Flammable Liquids (e.g., Benzene, Toluene, Ethanol)

- Oxidizing Substances

- Compressed Gases

- Environmentally Hazardous Agents

Refer to the COMAH Schedule (Annex I) for exact thresholds.

COMAH Safety Report – Contents

Required for Upper Tier establishments, the COMAH Safety Report must contain:

| Section | Description |

|---|---|

| Executive Summary | Overview of site operations and hazards |

| Risk Identification | Inventory, classification, storage conditions |

| Risk Assessment | Consequence modeling, probability estimates |

| Safety Management System | Policy, roles, training, procedures |

| Technical Measures | Design, control, barriers, instrumentation |

| Emergency Response | On-site and off-site plans |

| Environmental Impact | Spill modeling, air and water risk |

| Learning & Reporting | Previous incidents, near misses, improvement plans |

👉 Internal Link: QRA – Quantitative Risk Assessment

Safety Management Systems (SMS) Under COMAH

A robust SMS is central to complying with COMAH regulations. It includes:

- Leadership & Policy: Top management commitment to safety

- Risk Assessment & Control: HAZOP, LOPA, QRA, FERA

- Operational Controls: SOPs, permit to work (PTW), MOC

- Training & Competence: Job-specific and emergency training

- Monitoring & Audit: Internal/external audits, KPIs

- Incident Investigation: RCA, corrective action tracking

👉 Internal Link: HAZOP Study – A Detailed Guide

Risk Assessment Techniques Used in COMAH

- HAZID / HAZOP

- LOPA (Layer of Protection Analysis)

- QRA (Quantitative Risk Assessment)

- FERA (Fire and Explosion Risk Analysis)

- EERA (Escape, Evacuation and Rescue Analysis)

- SIMOPS (Simultaneous Operations)

- CFD Analysis for dispersion and explosion modeling

👉 Internal Link: PHAST-Based Air Dispersion Study

Emergency Planning and Preparedness

COMAH mandates two types of emergency plans:

1. On-site Emergency Plan

Prepared by the operator and includes:

- Roles and responsibilities

- Muster points

- Shutdown procedures

- Communication protocols

- First aid and firefighting

2. Off-site Emergency Plan

Prepared by the local authority, includes:

- Public warning systems

- Shelter-in-place or evacuation

- Coordination with hospitals, fire, police

- Media management

These plans must be tested every 3 years and reviewed after drills or incidents.

Public Information and Transparency

COMAH promotes openness with the public. For Upper Tier sites:

- Safety data and accident history must be disclosed

- Local communities must be informed of hazards

- Public access to Safety Reports (limited to non-confidential parts)

COMAH Compliance and Inspection

Competent Authorities (CAs) inspect COMAH facilities. In the UK, this includes:

- Health and Safety Executive (HSE)

- Environment Agency (EA)

- Scottish Environment Protection Agency (SEPA)

Inspection Focus Areas:

- SMS implementation

- Equipment reliability

- Audit systems

- Training records

- Emergency drills

Global Relevance and Equivalents

| Region | Equivalent Regulation |

|---|---|

| European Union | Seveso III Directive |

| India | MSIHC Rules 1989, Factories Act |

| USA | OSHA PSM (Process Safety Management), EPA RMP |

| Singapore | WSH (Major Hazards Installations) Regulations |

| Middle East | ADNOC, SABIC HSE Guidelines |

| Australia | Dangerous Goods Safety Act |

👉 Internal Link: List of Indian & International Process Safety Standards

COMAH Case Study – Ammonia Storage Terminal

Facility: Refrigerated Ammonia Tank (15,000 MT)

COMAH Tier: Upper Tier

Hazard: Toxic gas release

Action Taken:

- Detailed QRA and CFD dispersion modeling

- Control room relocated to low-exposure zone

- On-site emergency response plan revised

- Off-site mock drills coordinated with local hospitals

- Local population informed of hazards

Outcome: Approved by authorities with full COMAH compliance and integrated into community emergency planning.

Benefits of COMAH Compliance

| Area | Benefit |

|---|---|

| Safety | Reduced incident probability and impact |

| Business | Insurance, operational continuity, fewer shutdowns |

| Legal | Avoidance of fines, prosecutions |

| Reputation | Stakeholder trust and social license to operate |

| Environmental | Reduced pollution and ecosystem damage |

Common Challenges in COMAH Implementation

| Challenge | Solution |

|---|---|

| Large documentation workload | Use templates and third-party support |

| Low awareness among workers | Structured training and communication |

| Inadequate emergency drills | Use real-life scenarios and third-party evaluations |

| Resistance to data sharing | Foster transparency culture |

| Complex modeling | Use specialized tools (PHAST, FLACS, ALOHA) and experts |

FAQs

Q1: Is COMAH mandatory in India?

India follows MSIHC Rules, not COMAH, but the principles are aligned. Facilities handling threshold quantities of hazardous materials must comply with similar safety measures.

Q2: How often should Safety Reports be updated?

Every 5 years or immediately after major process changes or incidents.

Q3: Can a facility be downgraded from Upper Tier to Lower Tier?

Yes, by reducing or eliminating storage/processing of dangerous substances below lower thresholds.

Q4: Is CFD mandatory for COMAH studies?

Not mandatory but highly recommended for accurate consequence modeling, especially in toxic gas or explosion-prone environments.

Conclusion

COMAH compliance is more than a regulatory checkbox — it’s a strategic safety initiative that protects lives, assets, and the environment. From initial risk identification to emergency planning and public transparency, COMAH fosters a culture of prevention and preparedness.

Whether you’re designing a new hazardous facility or modernizing an old one, aligning your systems with COMAH principles ensures that you’re not just meeting regulatory expectations but building world-class resilience into your operations.