Introduction

In high-hazard process industries such as oil & gas, petrochemical, and chemical manufacturing, Emergency Systems Survivability Assessment (ESSA) plays a pivotal role in verifying whether emergency systems can operate reliably under accident conditions. ESSA ensures that these critical systems, responsible for protection, detection, shutdown, communication, evacuation, and fire suppression, remain functional during and after a major incident such as fire, explosion, or toxic gas release.

This article is a comprehensive guide for safety professionals, process engineers, and HSE managers, covering ESSA methodology, standards, assessment criteria, typical systems analyzed, real-life applications, and mitigation recommendations.

What Is ESSA?

Emergency Systems Survivability Assessment (ESSA) is a structured evaluation of the ability of critical emergency systems to perform their intended functions during or after hazardous events. These include:

- Fire and Gas Detection Systems

- Emergency Shutdown Systems (ESD)

- Communication and Alarm Systems

- Emergency Lighting

- Firewater Systems

- Emergency Power Supply (UPS, DG sets)

- HVAC systems for safe rooms

Objectives of ESSA

- Evaluate emergency systems’ resistance to hazardous events (e.g., blast, fire, smoke ingress)

- Ensure emergency functions are available when needed

- Identify and eliminate vulnerabilities in emergency system design or layout

- Demonstrate regulatory compliance (e.g., OISD, API, IEC, PNGRB)

- Recommend design enhancements for survivability improvement

When Is ESSA Required?

- New Greenfield project development

- Major brownfield facility expansion

- QRA indicates high risk to safety-critical systems

- As part of Fire & Explosion Risk Analysis (FERA)

- During Safety Case development

Key Terms and Concepts

| Term | Definition |

|---|---|

| ESSA | Emergency Systems Survivability Assessment |

| SCE | Safety Critical Equipment |

| TR | Temporary Refuge (e.g., Control Room, Safe Room) |

| PFP | Passive Fire Protection |

| IP | Ingress Protection Rating (e.g., IP65) |

| HSE | Health, Safety and Environment |

| ESD | Emergency Shutdown |

| SIL | Safety Integrity Level |

Methodology of ESSA

Step 1: Define the Scope

- List of safety-critical emergency systems

- Location of each asset on the layout

- Interface with other systems (e.g., F&G detectors with ESD)

Step 2: Hazard Identification (HAZID)

- Fire Scenarios: Jet fire, pool fire

- Explosion Scenarios: VCE, overpressure

- Gas Dispersion: Toxic/flammable gas clouds

- Smoke ingress into buildings

Step 3: Consequence Modeling

Use software such as:

- PHAST – dispersion and fire radiation

- FLACS – blast wave impact

- FDS – smoke modeling

Outputs:

- Radiation levels (kW/m²)

- Overpressure values (bar)

- Gas cloud concentrations (ppm)

- Smoke visibility index

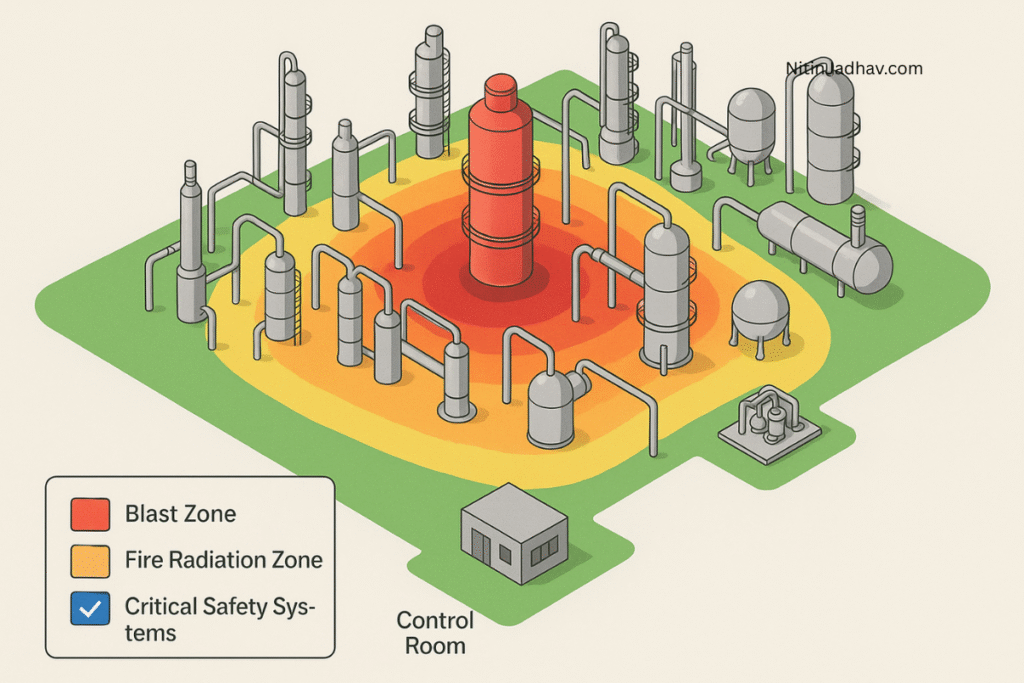

Step 4: Vulnerability Analysis

Assess survivability of each system against:

| Parameter | Criteria |

| Blast Resistance | 0.3 – 1.0 bar overpressure depending on equipment |

| Fire Resistance | 30 to 120 minutes based on criticality |

| Smoke Protection | TR visibility > 10 m; CO < 50 ppm |

| Vibration & Shock | Anti-seismic design for mounted equipment |

Use standards like:

- API 752/753 – Building siting & blast resistance

- IEC 61508 / 61511 – Functional Safety of SIS

- NFPA 72 – Fire detection systems

- OISD-STD-117 – Fire protection systems in oil installations

Systems Evaluated in ESSA

1. Fire & Gas Detection System

- Detector survivability under radiant heat and blast

- Sensor location redundancy

- Cabling protection via conduit or PFP

2. Emergency Shutdown System (ESD)

- SIL-rated PLCs in protected control cabinets

- Cable routing away from high-risk zones

- UPS backup for logic solvers

3. Firewater Pump System

- Above-ground or underground pump location

- Shielding from radiant heat >38 kW/m²

- Redundant jockey and diesel pumps

4. Alarm and Communication Systems

- PA system survivability under fire/smoke

- Integration with F&G systems

- Protected cabling with dual routing

5. Emergency Lighting & Signage

- Blast-proof fixtures

- Photoluminescent backup in escape paths

6. Safe Rooms / TR

- HVAC pressurization

- Airlock entry design

- 2-hour PFP walls, blast-proof windows

7. Power Supply (UPS, DG Sets)

- Separate room from fire-prone areas

- Cooling system protection

Real-World Failure Cases Due to Non-Survivable Systems

| Incident | Consequence | Root Cause |

| Piper Alpha (1988) | 167 fatalities | Control room lost due to fire and smoke ingress |

| Texas City (2005) | 15 deaths | Alarms disabled due to prior system damage |

| Jaipur IOC (2009) | Firewater pumps failed | Radiant heat exposure to pump house |

ESSA Reporting Format

- Executive Summary

- Emergency Systems Reviewed

- Hazardous Scenarios Considered

- Quantitative Analysis Summary (blast/fire impact values)

- Vulnerability Ratings (High / Medium / Low)

- Recommendations & Mitigation Plan

Mitigation Strategies

1. Passive Protection

- Intumescent coating

- Blast-proof enclosures

- Thermal shielding for fire pumps

2. Design Redundancy

- Dual detectors or dual cabling

- Hot standby PLCs

- Firewater ring mains with sectional valves

3. Equipment Relocation

- Shift critical assets outside 5 kW/m² zone

- Avoid location near congested explosion zones

4. Procedural Improvements

- Weekly check of UPS health

- Monthly firewater pump test

- Emergency drills simulating loss of system

Integration with Other Safety Studies

- QRA – Provides hazard scenario input and frequency

- FERA – Fire/explosion modeling for ESSA inputs

- HAZOP – Identifies critical failure modes

- LOPA – Verifies IPL effectiveness under hazard exposure

- COMAH / Safety Case – Regulatory requirement to demonstrate SCE survivability

Related Articles on NitinJadhav.com:

- Fire and Gas Detector Mapping Study

- FERA – Fire and Explosion Risk Analysis

- LOPA Study Methodology

- Control of Major Accident Hazards (COMAH)

Conclusion

Emergency Systems Survivability Assessment (ESSA) is a vital component of a comprehensive process safety management system. Without survivable emergency systems, the best-designed plant could fail catastrophically under hazardous conditions.

By systematically identifying vulnerabilities and implementing robust mitigation strategies, ESSA ensures that safety-critical systems work when needed the most — during emergencies. This significantly enhances the facility’s resilience, protects personnel, and ensures regulatory compliance.

If you’re planning a new project or upgrading safety infrastructure, don’t overlook ESSA — it’s your last line of defense.