Introduction

Industries handling petroleum, natural gas, and other hydrocarbons operate in environments prone to fires, explosions, toxic gas releases, and natural or man-made disasters. In such sectors, a well-structured emergency response framework is not a choice—it’s a legal necessity and a safety imperative.

Recognizing this, the Petroleum and Natural Gas Regulatory Board (PNGRB) issued comprehensive regulations in 2010, later amended in 2020, mandating every hydrocarbon-handling facility to develop a detailed Emergency Response and Disaster Management Plan (ERDMP).

This article provides an in-depth understanding of the ERDMP concept, structure, legal requirements, industry applicability, third-party accreditation, and integration with overall process safety management.

👉 Internal Link: List of Process Safety Studies

What is ERDMP?

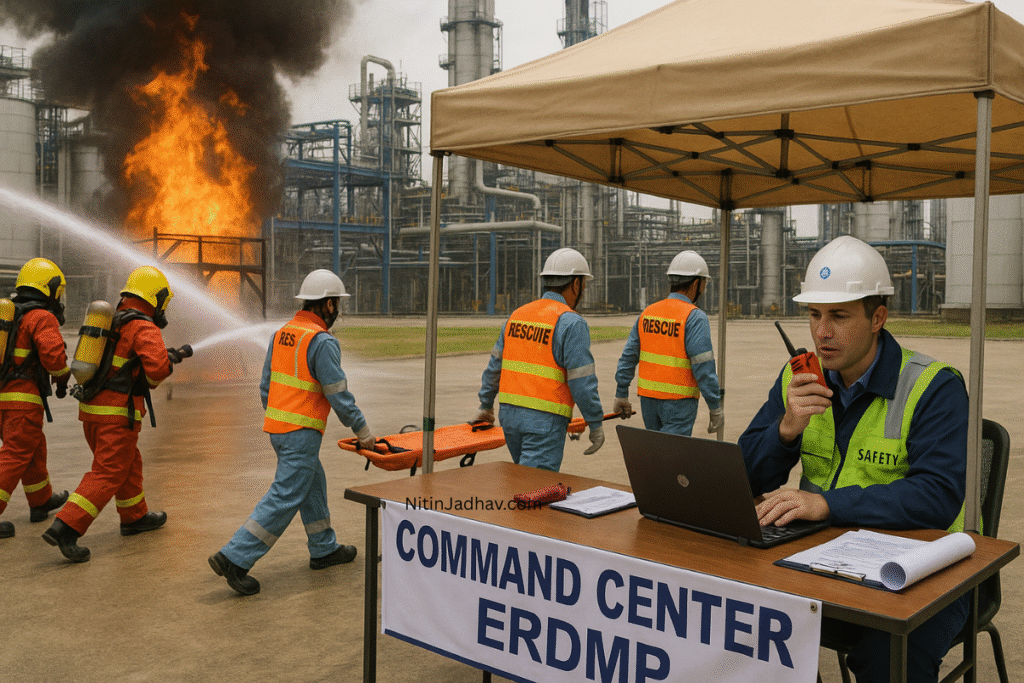

Emergency Response and Disaster Management Plan (ERDMP) is a structured and documented procedure outlining:

- How to prevent, prepare for, respond to, and recover from emergencies in hydrocarbon installations

- The roles, responsibilities, and resources needed for safe execution

- Procedures for early detection, effective communication, safe evacuation, and disaster mitigation

It’s a legal requirement under PNGRB ERDMP Regulations, 2010 and its Amendment in 2020.

PNGRB ERDMP Regulations – Overview

| Regulation | Description |

|---|---|

| PNGRB ERDMP 2010 | Introduced emergency planning obligations for all hydrocarbon facilities |

| Amendment 2020 | Updated content structure, scope, and validation procedures including TPIA |

👉 External Link: PNGRB Official Website

Applicability of ERDMP Regulations

The regulations apply to a wide range of facilities in the oil & gas value chain, including:

- Refineries, Gas Processing Plants, LNG Terminals

- Gas Pipelines (natural gas, propane, butane)

- Liquid Petroleum Product Pipelines

- LPG/Propane/Butane Bottling Plants

- City Gas Distribution (CGD) Networks

- POL Retail Outlets (Petrol Pumps, CNG Stations)

- Petroleum Road Tanker Transporters

- Commercial Petroleum Storage Depots

- LNG Storage and Dispensing Facilities

- Any other notified installation by the Board

These facilities must prepare a site-specific ERDMP, implement it, and get it certified by an accredited Third-Party Inspection Agency (TPIA).

👉 Internal Link: Fire and Gas Mapping Study

Structure of the ERDMP Document

According to PNGRB, the ERDMP should include the following sections:

1. Introduction and Objectives

- Site overview

- Purpose of ERDMP

- Legal compliance references

2. Risk and Hazard Identification

- Hazardous inventory

- Hazard scenarios (fire, explosion, toxic release, natural calamities)

- QRA and FERA findings

3. Emergency Organization Structure

- Chief Incident Controller (CIC)

- Site Incident Controller (SIC)

- Emergency Control Team (ECT)

- Rescue, Fire, Medical, Communication Teams

4. Communication Protocols

- External agencies (police, fire, NDRF, PESO)

- Internal hierarchy

- Public notification plan

5. Emergency Equipment Details

- Firewater systems

- Gas detectors

- Breathing apparatus

- Emergency shutdown systems

6. Mutual Aid and External Coordination

- Nearby industries

- Hospitals

- Disaster management authorities

- Local administration

7. Standard Operating Procedures (SOPs)

- Fire, gas leak, explosion, toxic release, earthquake, sabotage

- Site shutdown, muster, evacuation

8. Mock Drills and Training Programs

- Types: Tabletop, onsite, offsite

- Frequency: Quarterly and annually

- Record keeping and analysis

9. Post-Emergency Procedures

- Recovery planning

- Incident investigation

- Learning and improvement

10. Annexures

- Site maps

- Layout drawings

- Emergency contact list

- MSDS

- Training calendar

👉 Internal Link: FERA – Fire and Explosion Risk Analysis

Certification by Third-Party Inspection Agency (TPIA)

After preparing the ERDMP, it must be audited and certified by a TPIA accredited by PNGRB.

TPIA Responsibilities:

- Verify emergency systems

- Assess risk identification accuracy

- Review SOPs and ERP structure

- Conduct mock drill evaluations

- Submit compliance report to PNGRB

The list of approved TPIAs is published and regularly updated on the PNGRB website.

Risk Scenarios Covered in ERDMP

| Hazard | Scenario Examples |

|---|---|

| Fire | Tank farm fire, pump seal leak ignition |

| Explosion | VCE in gas processing area |

| Toxic Gas Release | H₂S leak in refinery, LPG vapor dispersion |

| Pipeline Rupture | Natural gas pipeline failure |

| Sabotage/Arson | POL retail outlet fire |

| Natural Disasters | Earthquake, cyclone, lightning strike |

| Transport Emergency | Road tanker rollover and leak |

👉 Internal Link: PHAST Air Dispersion Study

Roles and Responsibilities in an Emergency

| Role | Responsibility |

|---|---|

| Chief Incident Controller | Overall control, media, external coordination |

| Site Incident Controller | On-ground decision-making, resource deployment |

| Emergency Control Team | Responds to fire, gas leak, or rescue operations |

| Communication Team | Alerts internal/external stakeholders |

| Security Team | Site control, crowd management |

| Medical Team | First aid, casualty triage, hospital liaison |

Mock Drills: Frequency and Types

| Drill Type | Description | Frequency |

|---|---|---|

| Tabletop Drill | Simulated discussion | Quarterly |

| Onsite Drill | Physical drill on-site | Half-yearly |

| Offsite Drill | Involving external agencies | Annually |

Drill records must include:

- Scenario description

- Participants

- Response time

- Observations

- Corrective actions

Integration with Process Safety Management

ERDMP is not a standalone document. It complements and connects with:

- HAZOP Study → Provides deviations and risk scenarios

- QRA / FERA → Supports impact estimation

- SIL Study → Ensures protective layers function during emergencies

- LOPA → Assesses effectiveness of safeguards

- F&G Mapping → Optimizes alarm and shutdown logic

👉 Internal Link: SIL Study – Safety Integrity Level

ERDMP for City Gas Distribution and Retail Outlets

Even small-scale operations such as CGD networks and petrol pumps require a tailored ERDMP.

For CGD:

- Pipeline rupture or leakage

- CNG station overpressure

- Emergency shutdown protocols

- Neighborhood notification

For POL Retail Outlets:

- Underground tank fire

- Vehicle refueling fires

- Road tanker unloading safety

- Public crowd management

Challenges in ERDMP Implementation

| Challenge | Solution |

|---|---|

| Outdated layouts | Conduct periodic site survey |

| Lack of trained personnel | Conduct quarterly training |

| No coordination with local agencies | Pre-mock drills involving DMP, NDRF |

| Ignorance of TPIA process | Partner with accredited TPIAs early |

| Poor documentation | Use digital ERP and cloud backups |

Post-Emergency Recovery Planning

- Damage assessment of assets and environment

- Business continuity strategy

- Re-entry protocols

- Media and stakeholder communication

- Root cause analysis

- Corrective action tracking

Case Study – LNG Terminal ERDMP Implementation

Facility: 5 MTPA LNG terminal

Hazards Identified: Cryogenic spill, VCE, LNG tank roof fire

ERDMP Highlights:

- Dedicated firewater system with monitors

- Mutual aid agreement with coast guard

- High-volume foam system

- Local community awareness campaign

- TPIA approval received within 45 days

Outcome: Successfully conducted offsite drill with 350+ stakeholders; praised by PNGRB and State DMP.

FAQs

Q1: Is ERDMP mandatory for small oil and gas companies?

Yes. Even small POL outlets and CGD installations must prepare and implement ERDMP per PNGRB guidelines.

Q2: How often should ERDMP be updated?

ERDMP must be reviewed annually and revised whenever there are significant changes to facility layout, materials, or operations.

Q3: What happens if a facility doesn’t comply?

PNGRB may issue show-cause notices, penalize, or revoke licenses for non-compliance.

Q4: Can ERDMP be developed internally?

Yes, but it must be validated and certified by a PNGRB-approved Third-Party Inspection Agency (TPIA).

Conclusion

An effective Emergency Response and Disaster Management Plan (ERDMP) is not just a regulatory requirement—it’s a cornerstone of risk mitigation, operational resilience, and environmental protection in hazardous industries.

Whether you’re managing a sprawling refinery or a small CNG dispensing station, ERDMP provides a proven framework to predict, prevent, and respond to emergencies. With PNGRB’s updated guidelines and mandatory third-party audits, organizations now have a clear pathway to build robust, compliant, and effective response systems.

Prepare. Protect. Perform. That’s what a solid ERDMP empowers you to do.