Introduction

In the realm of process safety management, identifying potential hazards is only half the job. The real challenge lies in determining whether the existing safety systems are adequate—or if more layers of protection are needed.

That’s where LOPA (Layers of Protection Analysis) comes in. LOPA is a semi-quantitative risk assessment tool used to determine if the current safeguards (Independent Protection Layers or IPLs) sufficiently reduce the risk of a hazardous event.

This comprehensive guide explains everything you need to know about LOPA studies—from methodology and key concepts to risk criteria, calculations, examples, and how it supports SIL (Safety Integrity Level) determination.

👉 Internal Link: Comprehensive List of Process Safety Studies

1. Objectives of LOPA

LOPA serves multiple critical functions in the process safety lifecycle:

- Assess the risk associated with hazardous scenarios

- Evaluate the adequacy of existing protection layers

- Identify the need for additional safeguards

- Provide a structured and defensible risk-based decision-making process

- Support SIL determination for safety instrumented functions (SIFs)

LOPA is widely applied in the oil & gas, petrochemical, polyolefins, and chemical sectors—aligned with regulations such as OISD, API RP 754, NFPA, and IEC 61511.

2. Key Concepts in LOPA

2.1 Initiating Events (IEs)

An initiating event is a failure or abnormal condition that may start a hazardous scenario.

Examples:

- Control valve stuck open

- Operator error (e.g., opening the wrong valve)

- Pump failure

- Power or utility outage

- Earthquake or lightning strike

The frequency of each IE is estimated using:

- Historical data

- Industry databases (e.g., OREDA)

- Engineering judgement

2.2 Independent Protection Layers (IPLs)

An Independent Protection Layer is a safeguard that:

- Functions independently of other layers

- Has high reliability

- Detects, acts upon, and mitigates the hazard

- Is auditable and maintainable

Typical IPLs include:

- Basic Process Control System (BPCS)

- Safety Instrumented System (SIS)

- Pressure Relief Valves (PRVs)

- Operator Interventions with alarms

- Containment systems (bunds, dikes)

- Emergency shutdown systems (ESD)

Each IPL is assigned a Risk Reduction Factor (RRF), usually the inverse of its Probability of Failure on Demand (PFD).

👉 Internal Link: SIL Study and SIS Integration

2.3 Consequence Severity

LOPA uses consequence categories (from minor to catastrophic) based on:

- Human health and fatalities

- Environmental damage

- Equipment damage and economic loss

This defines the Target Risk Tolerance.

2.4 Target Risk Criteria

Every organization sets risk thresholds, such as:

| Scenario | Tolerable Frequency |

|---|---|

| Catastrophic with multiple fatalities | 1 × 10⁻⁵ per year |

| Serious injury or major damage | 1 × 10⁻⁴ per year |

| Minor injury or loss | 1 × 10⁻³ per year |

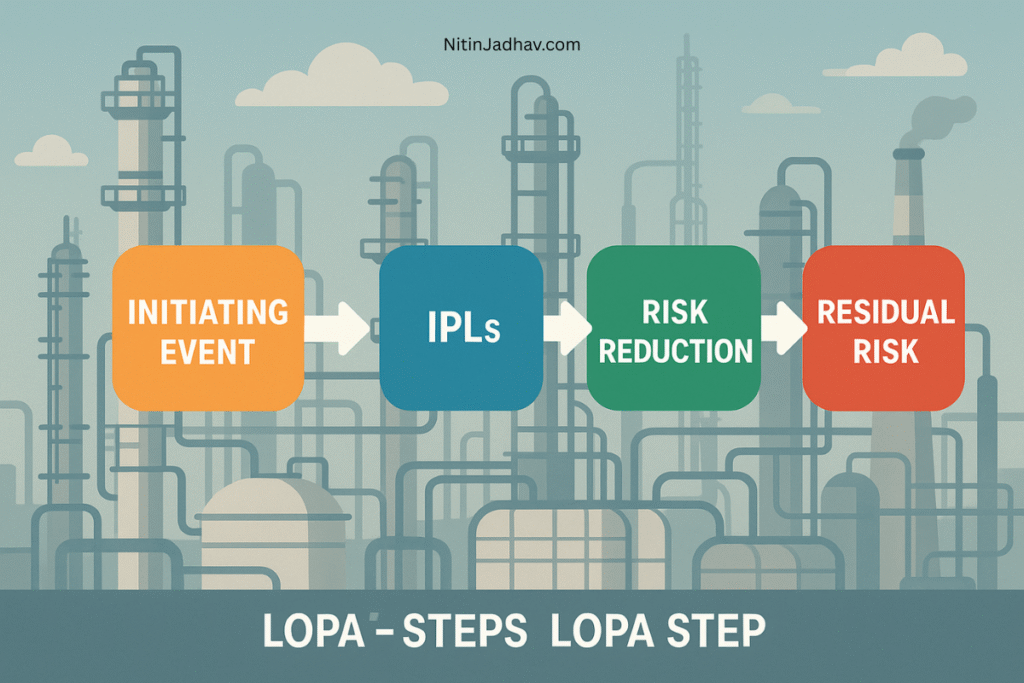

3. LOPA Methodology

Step 1: Define the Scenario

- Use HAZOP outputs or incident history

- Identify hazardous events and consequence category

Step 2: Determine Initiating Event Frequency (IEF)

- Use failure rates from databases or expert judgment

- Example: Pressure control valve fails open → frequency = 1/1000/year

Step 3: Identify IPLs and Their Effectiveness

| IPL | PFD | RRF |

|---|---|---|

| SIS (SIL 2) | 0.01 | 100 |

| Pressure Relief Valve | 0.1 | 10 |

| Operator response | 0.1 | 10 |

Verify that IPLs meet independence, auditability, and reliability standards.

Step 4: Calculate Total Risk Reduction Factor (RRF)

Total RRF = RRF₁ × RRF₂ × RRF₃ …

Or

PFD_total = PFD₁ × PFD₂ × PFD₃ …

Step 5: Determine Residual Risk

Residual Risk = Initiating Event Frequency × PFD_total

Compare this with Target Risk Criteria.

Step 6: Decide Action

| Result | Action |

|---|---|

| Risk ≤ Target | No additional IPLs required |

| Risk > Target | Add more safeguards or redesign process |

4. Example LOPA Study

Scenario: Reactor overpressure due to control valve failure

Initiating Event Frequency: 1 in 1,000 years (1×10⁻³)

Independent Protection Layers:

| IPL | RRF | PFD |

|---|---|---|

| Pressure Relief Valve | 10 | 0.1 |

| SIS | 100 | 0.01 |

| Operator Intervention | 10 | 0.1 |

Residual Risk Calculation:

PFD_total = 0.1 × 0.01 × 0.1 = 1×10⁻⁴

Residual Risk = 1×10⁻³ × 1×10⁻⁴ = 1×10⁻⁷

Acceptable Limit: 1×10⁻⁵/year → ✅ Risk is acceptable

5. LOPA and SIL Determination

LOPA is commonly used to determine the SIL required for a Safety Instrumented Function (SIF).

| SIL | PFD Range | Risk Reduction |

|---|---|---|

| SIL 1 | 0.1 to 0.01 | 10–100 |

| SIL 2 | 0.01 to 0.001 | 100–1000 |

| SIL 3 | 0.001 to 0.0001 | 1000–10,000 |

| SIL 4 | < 0.0001 | >10,000 (rarely used in process industry) |

👉 Internal Link: Safety Integrity Level (SIL) Explained

6. Documentation Requirements in LOPA

- LOPA Worksheets

- Initiating Event Justifications

- IPL Independence and Reliability Justifications

- Risk Criteria Definitions

- Final Recommendations

- SIL Assignment

7. LOPA Software Tools

| Software | Features |

|---|---|

| exSILentia (by exida) | Integrated HAZOP, LOPA, SIL |

| PHAWorks RA Edition | Customizable LOPA templates |

| BowTieXP | Visual risk scenarios |

| Isograph Reliability Workbench | Fault tree + LOPA integration |

| SLM® by aeSolutions | SIS lifecycle + LOPA |

8. Integration with Other Safety Studies

| Study | Role in LOPA |

|---|---|

| HAZOP | Source of initiating scenarios |

| QRA | Background risk evaluation |

| SIL Study | LOPA determines target SIL |

| COMAH/ERDMP | Emergency planning input |

| F&G Mapping | Defines need for alarm systems and ESD triggers |

👉 Internal Link: QRA vs FERA vs EERA

9. Benefits of LOPA

- Semi-quantitative and structured

- Objective basis for adding or justifying safeguards

- Helps avoid overdesign or underprotection

- Enhances decision-making for budget allocation

- Supports compliance with IEC 61511, API RP 754, OISD Guidelines

10. Common Challenges and Best Practices

| Challenge | Solution |

|---|---|

| Incomplete initiating event list | Start from validated HAZOP |

| IPLs not truly independent | Review interlocks and design logic |

| Over-reliance on operator intervention | Use automation where risk is high |

| Unclear risk tolerance criteria | Use company risk matrix and align with industry norms |

| No SIL link | Always trace LOPA findings to SIL assignment |

11. Indian Industry Perspective on LOPA

In India, LOPA is now a preferred tool in:

- Refinery MOCs

- Fertilizer and petrochemical plants

- PSM compliance audits

- SIL verification and alarm rationalization

Used alongside:

- OISD 150 / 244 / 206

- PESO guidelines for hazardous installations

- PNGRB’s ERDMP requirements

12. FAQs

Q1: Is LOPA a regulatory requirement?

While not explicitly required, LOPA is globally recognized and often expected in compliance with IEC 61511, API RP 754, and corporate PSM frameworks.

Q2: How often should LOPA be reviewed?

Every 5 years, or after any significant process change, incident, or equipment upgrade.

Q3: Can LOPA replace HAZOP?

No. LOPA is used after HAZOP, not instead of it. HAZOP identifies scenarios; LOPA assesses risk reduction.

Q4: Can operator actions be counted as IPLs?

Yes, but only if they meet timing, training, and procedural reliability criteria.

13. Conclusion

LOPA is more than just another risk assessment method—it’s a strategic decision-making tool that bridges the gap between qualitative and quantitative safety analysis.

By assessing the sufficiency of independent protection layers, quantifying risk, and aligning outcomes with target criteria, LOPA plays a crucial role in avoiding catastrophic failures and optimizing investments in safety systems.

Its integration with SIL studies, PSM frameworks, and international codes ensures that safety is not left to chance—but is built into the design, operation, and culture of an organization.