Introduction

In the high-risk, high-investment world of oil & gas and chemical industries, maximizing uptime and minimizing equipment failure are essential. The Reliability, Availability, and Maintainability (RAM) study provides a systematic approach to understanding and improving the performance of systems critical to production and safety. This article offers a detailed, SEO-optimized guide on RAM analysis, focusing on methodology, tools, standards, and applications, particularly in upstream and downstream process facilities.

1. What is RAM?

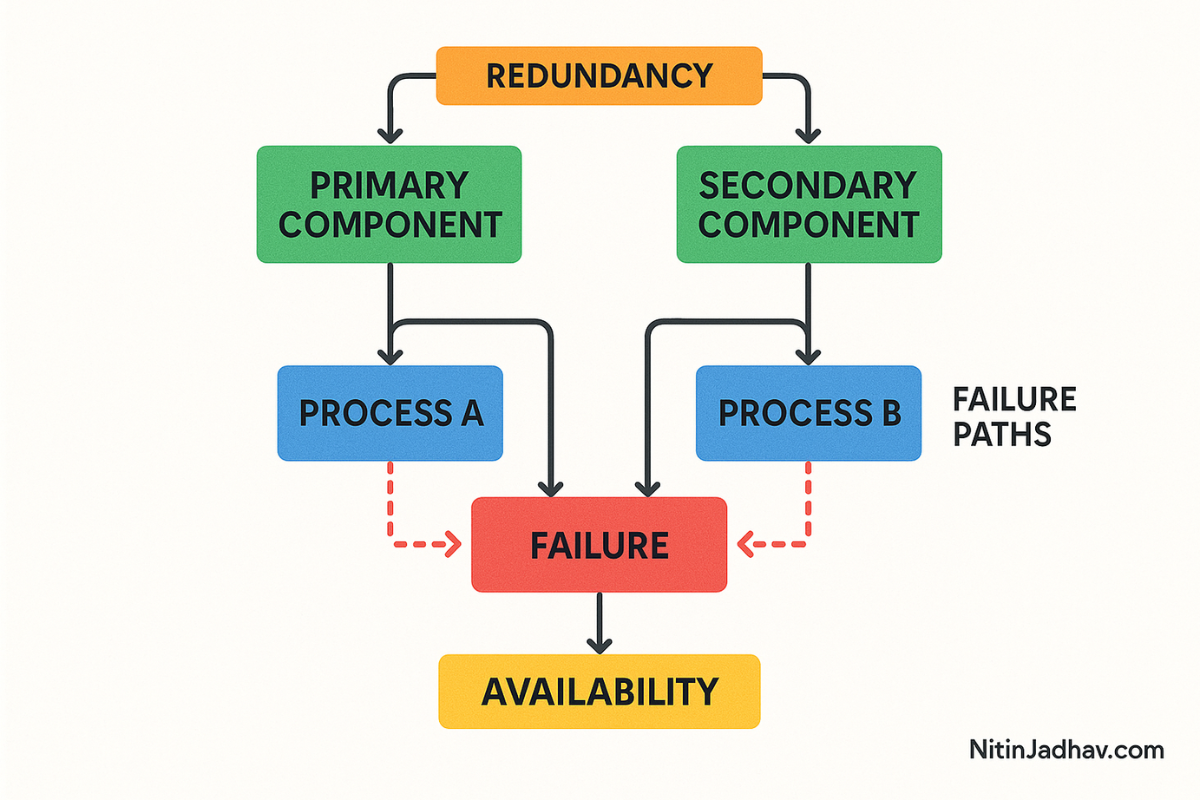

Reliability, Availability, and Maintainability (RAM) is a performance assessment technique used to evaluate the expected performance and readiness of systems over time. It identifies the likelihood and impact of equipment failures and proposes strategies to mitigate them.

- Reliability: Probability that a system will perform its intended function without failure for a specified period.

- Availability: Probability that a system is operational when needed.

- Maintainability: Ease and speed with which a failed system can be restored to service.

2. Objectives of a RAM Study

- To improve system design for optimal uptime

- To minimize unplanned shutdowns and equipment failures

- To identify critical equipment and system dependencies

- To optimize maintenance strategies

- To support investment decisions using quantitative performance predictions

3. Key Steps in Performing RAM Analysis

3.1 Identification of Essential Systems and Equipment

The first step involves determining which systems and equipment directly affect the facility’s injection or production availability. These are typically high-value, high-risk assets whose failure can halt operations.

3.2 Gathering of Reliability Data

Reliability data includes:

- Mean Time Between Failures (MTBF)

- Mean Time To Repair (MTTR)

- Failure modes and effects

- Vendor data, historical records, and industry databases (e.g., OREDA, IEEE)

3.3 Construction of Reliability Block Diagrams (RBDs)

RBDs represent the logical configuration of systems:

- Series systems

- Parallel redundancies

- Standby components

RBDs are developed using:

- PFDs (Process Flow Diagrams)

- P&IDs (Piping and Instrumentation Diagrams)

- Utility Flow Diagrams (UFDs)

- Block Flow Diagrams (BFDs)

3.4 RAM Modelling Using Software Tools (e.g., MAROS)

MAROS (developed by DNV) is an industry-standard tool for RAM modeling. It simulates:

- Equipment performance over a lifecycle

- Production loss scenarios

- Maintenance impact

- Spares logistics

3.5 Identifying Critical Systems and Equipment

Based on the simulation, the equipment and systems are ranked according to:

- Downtime impact

- Frequency of failure

- Redundancy configuration

- Repair effort

4. RAM Inputs and Assumptions

- Equipment configuration (1oo2, 2oo3, N+1, etc.)

- Failure and repair data (from OREDA or OEMs)

- Maintenance strategy (corrective, preventive, predictive)

- Logistic delays (crew travel time, spares availability)

- Operating environment (corrosive, offshore, remote)

5. Output and Interpretation

RAM study provides the following deliverables:

- System availability report

- Equipment criticality ranking

- Maintenance strategy optimization

- Bottleneck identification

- Reliability improvement roadmap

6. Benefits of RAM Study

- Operational Reliability: Reduce downtime and increase system uptime

- Economic Performance: Prevent production losses and avoid unnecessary CAPEX

- Regulatory Compliance: Supports integrity and safety compliance with standards like API 581, ISO 14224, and IEC 60300

- Maintenance Efficiency: Enables Risk-Based Maintenance (RBM) planning

7. Integration with Other Safety and Risk Studies

- HAZOP/LOPA: RAM can provide criticality ranking which helps prioritize scenarios in HAZOP.

- QRA: RAM data feeds QRA models with real-world failure probabilities.

- FMEA/FMECA: RAM complements failure analysis by estimating impact severity and maintenance needs.

- SIL Study: RAM data supports setting Safety Integrity Level (SIL) targets.

8. Software Tools for RAM Studies

- MAROS: Advanced RAM analysis for upstream/downstream oil & gas facilities

- TARAS: Tailored for FPSO and offshore systems

- Isograph Availability Workbench

- ReliaSoft BlockSim

- SpareLogic: Spare part optimization and logistics planning

9. Case Study Example: FPSO RAM Analysis

Objective: Improve uptime of a water injection system on an FPSO

Steps Taken:

- Identification of 8 critical equipment in injection train

- Data collection from 3 years of operation logs

- Development of RBDs in MAROS

- Scenario simulation for dual-pump redundancy vs. single pump

- Outcome: Dual-redundancy increased uptime by 6.8%, with a payback period of 14 months

10. Challenges in RAM Implementation

- Incomplete or poor-quality data

- Resistance to changes in maintenance or spares strategy

- Tool complexity and need for skilled analysts

- Aligning RAM results with actual operations

11. Best Practices for RAM Success

- Start early in project lifecycle (FEED or pre-FEED)

- Integrate with design engineering and operations teams

- Use verified industry databases for failure data

- Regularly update model with field feedback

- Align RAM with asset integrity and HSE programs

12. International Standards Referenced in RAM

- ISO 14224 – Reliability and Maintenance Data for Equipment

- IEC 60300-3-1 – RAM Analysis Techniques

- API 581 – Risk-Based Inspection

- DNV-RP-A203 – Technology Qualification

- NORSOK Z-008 – Criticality Classification

Conclusion

RAM analysis is a cornerstone of modern reliability engineering. For high-capital, safety-sensitive industries, RAM is not just about reducing failures—it is about making data-driven decisions that optimize system performance, reduce OPEX, improve safety, and increase profitability.

By integrating RAM into the early phases of design, and regularly updating it through the lifecycle of a facility, industries can stay ahead of risks and achieve sustainable operational excellence.

Related Articles on NitinJadhav.com:

- HAZOP Study Methodology & Examples

- QRA – Quantitative Risk Assessment Explained

- SIL Study – Safety Integrity Level Determination

- Maintenance Planning Using FMECA

External References: