Introduction

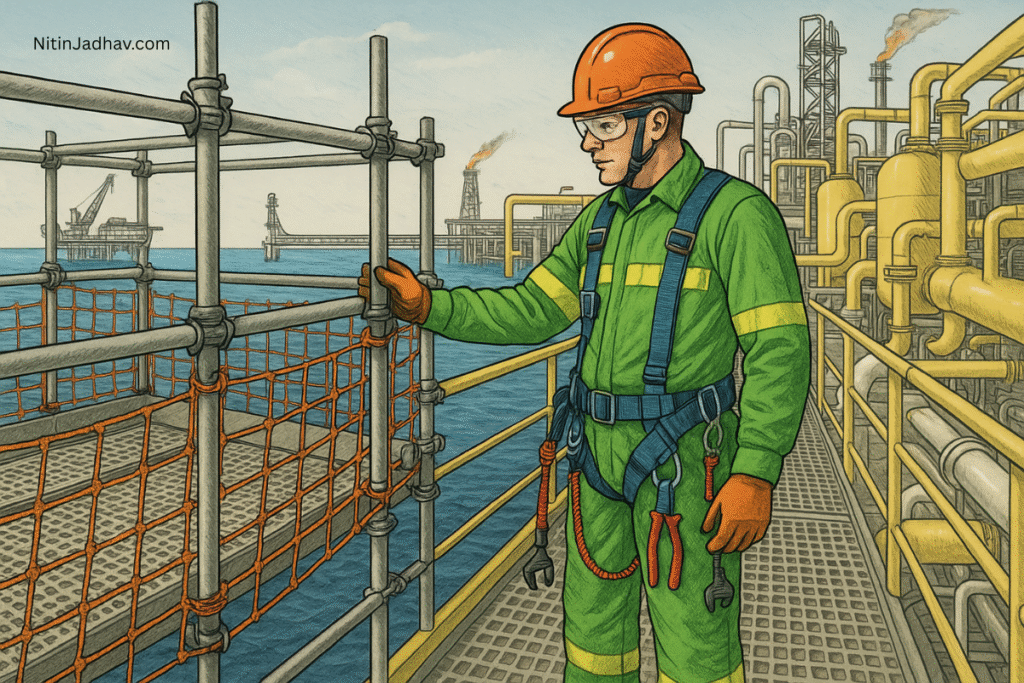

In high-risk industrial environments, especially in oil & gas, offshore platforms, construction, and process industries, Dropped Objects (DOs) represent a critical safety concern. A Dropped Object Study (DOS) is a systematic evaluation designed to identify, assess, and mitigate the risks associated with objects that may fall due to gravity or unintended movement, particularly during lifting and maintenance activities.

This article provides a detailed and SEO-optimized overview of the Dropped Object Study, its objectives, methodology, risk analysis components, and practical recommendations, tailored specifically for safety professionals in oil & gas and process sectors.

What is a Dropped Object?

A dropped object is defined as any object that falls from its previous static position under its own weight or due to external forces (such as vibration, wind, or impact) and has the potential to cause injury, fatalities, equipment damage, or environmental harm.

These objects may include tools, lifting accessories, scaffolding materials, structural components, or even loose items stored at height.

Why Conduct a Dropped Object Study?

Key Objectives of the DOS:

- Identify lifted objects used in daily operations and maintenance activities

- Evaluate dropped object types during different phases (construction, operation, turnaround)

- Assess current protective systems and barriers in place

- Calculate drop frequency and probability

- Estimate impact energy to determine potential damage

- Propose additional safeguards if existing controls are inadequate

Industry Relevance:

- Offshore platforms (rigs, FPSOs)

- Refineries and petrochemical complexes

- Heavy industrial construction

- Maintenance and crane lifting zones

Types of Dropped Objects

1. Static Dropped Objects

- Items that fall without being touched or disturbed

- Causes: corrosion, vibration, improper fastening

2. Dynamic Dropped Objects

- Objects that fall due to moving equipment or human interaction

- Causes: improper rigging, lifting gear failure, collisions

Consequences of Dropped Objects

- Fatal or severe injuries to personnel

- Structural damage to critical process equipment

- Escalation into fire, explosion, or toxic release

- Production downtime and financial losses

- Legal and compliance penalties

Dropped Object Study Methodology

A robust Dropped Object Study involves a step-by-step approach that aligns with industry best practices, such as those recommended by Dropped Object Prevention Scheme (DROPS), API RP 2D, and ISO 45001.

Step 1: Description of Lifting Operations

- List all lifting operations (routine and non-routine)

- Identify locations: pipe racks, offshore modules, platforms, tank farms

- Review all crane lifting zones, scaffolding platforms, and suspended loads

Step 2: Hazard Identification

Use site inspections, checklists, and design reviews to identify:

- Loose tools or unsecured items

- Equipment stored above walkways

- Sling failure potential

- Vibration-prone connections

Step 3: Likelihood Estimation of Hitting Target Area

Evaluate:

- Frequency of operation (daily, weekly, shutdown)

- Size, shape, and height of the object

- Wind or operational load movement

- Location of personnel below the object

Step 4: Impact Energy Assessment

The Impact Energy (IE) is calculated using:

IE=m×g×hIE = m \times g \times h

Where:

- m = mass of object (kg)

- g = gravity (9.81 m/s²)

- h = height of fall (meters)

The result is expressed in Joules (J) and used to categorize severity levels:

| Energy Level (J) | Potential Consequence |

|---|---|

| < 5 J | Minor injury or negligible |

| 5 – 50 J | Moderate injury (cuts, bruises) |

| 50 – 500 J | Major injury or fracture |

| > 500 J | Fatal or catastrophic damage |

Step 5: Risk Matrix and Probability Calculation

- Use a risk matrix to plot likelihood vs. severity

- Determine Probability of Occurrence based on operational data or past incident history

- Assign Risk Rankings (Low, Medium, High, Extreme)

Step 6: Existing Protection Systems Evaluation

Evaluate adequacy of:

- Tool tethering systems

- Netting, trays, and cages

- Exclusion zones or barriers

- Maintenance procedures

- PPE (hard hats, face shields)

Step 7: Recommendations & Mitigation Measures

- Relocate non-essential items at height

- Install toe boards, handrails, safety nets

- Enforce dropped object checklists before lifts

- Training and awareness for lifting crew

- Integrate DO prevention in Permit-to-Work (PTW) system

Common Dropped Object Scenarios

| Scenario | Description |

|---|---|

| Tool dropped from scaffold | A wrench not tethered falls from a height of 10 m |

| Slings slipping during lifting | Bundle of pipes tilts and drops load due to wrong sling angle |

| Wind-induced fall | Lightweight equipment blown off an offshore deck |

| Corroded fixtures | Light fittings detached due to corrosion of bolts |

Quantifying Risk Using Dropped Object Calculator

Many industries now use dedicated software tools and Excel models to quantify dropped object risk:

- Impact Energy Calculator

- Drop Probability Matrix

- DOS Register (Object ID, Location, Weight, Height, Energy, Risk Level)

Example:

- Object: Manual Valve Handle

- Weight: 1.5 kg

- Height: 8 m

- Impact Energy = 1.5 × 9.81 × 8 = 117.72 J → High Risk

Integration with Other Safety Studies

The Dropped Object Study complements other safety studies like:

- HAZOP Study – For process deviations involving lifting impact

- LOPA – When dropped object could initiate critical failure

- QRA – Used for modeling escalation events due to dropped object triggering a fire

- SIMOPs – When lifting overlaps with hot work or confined space entries

Read: LOPA Study – Methodology & Applications

Read: SIMOPs – Identification and Risk Control

Regulatory & Industry Guidelines

- Dropped Objects Prevention Scheme (DROPS) guidelines

- API RP 2D – Offshore lifting operations

- OISD Guidelines – Safety during erection and construction

- IS 14489 – Occupational safety audit protocol

- OSHA 1926 Subpart N – Lifting and rigging safety

Sample Dropped Object Register Format

| S.No | Object | Weight (kg) | Height (m) | Energy (J) | Location | Protection Available | Risk Ranking | Action Required |

|---|---|---|---|---|---|---|---|---|

| 1 | Spanner | 0.8 | 12 | 94.2 | Platform B | None | High | Tether tool |

Best Practices in Dropped Object Prevention

- Tool Control Systems: Track and tether all tools

- Pre-Lift Checklist: Review object stability, rigging, sling condition

- Barricading Work Zones: Restrict access below lifting areas

- Inspection Routines: Include drop risk during HSE walkdowns

- Awareness Training: Conduct sessions on real incident case studies

Case Study Example

Incident Summary:

In an offshore rig, a 2.5 kg clamp fell from a height of 15 meters during a maintenance activity. The clamp missed a technician by just 0.5 meters.

Root Cause:

- Unsecured part left on pipe rack

- No dropped object check prior to job closure

Corrective Actions:

- Implementation of mandatory dropped object inspection post-work

- Enhanced tethering policy for all temporary items

- Revision of PTW checklist to include DO control section

Conclusion

Dropped Object Studies (DOS) are crucial for high-risk environments like oil & gas, offshore rigs, and heavy industrial zones. They not only help prevent fatal injuries and equipment loss but also ensure regulatory compliance and operational continuity.

By following a structured study approach, calculating impact energy, and applying engineering/administrative safeguards, organizations can greatly reduce dropped object incidents.

Related Articles on NitinJadhav.com

- Emergency Response & Disaster Management Plan

- HAZOP Study: A Detailed Guide

- Control of Major Accident Hazards (COMAH)

External References

Stay safe. Stay compliant. Minimize risks from above. ✅