Risk Management

The Risk Management category on NitinJadhav.com is dedicated to helping professionals in process industries, EPC projects, and plant operations understand, assess, and mitigate risks to ensure safe, efficient, and compliant industrial environments.

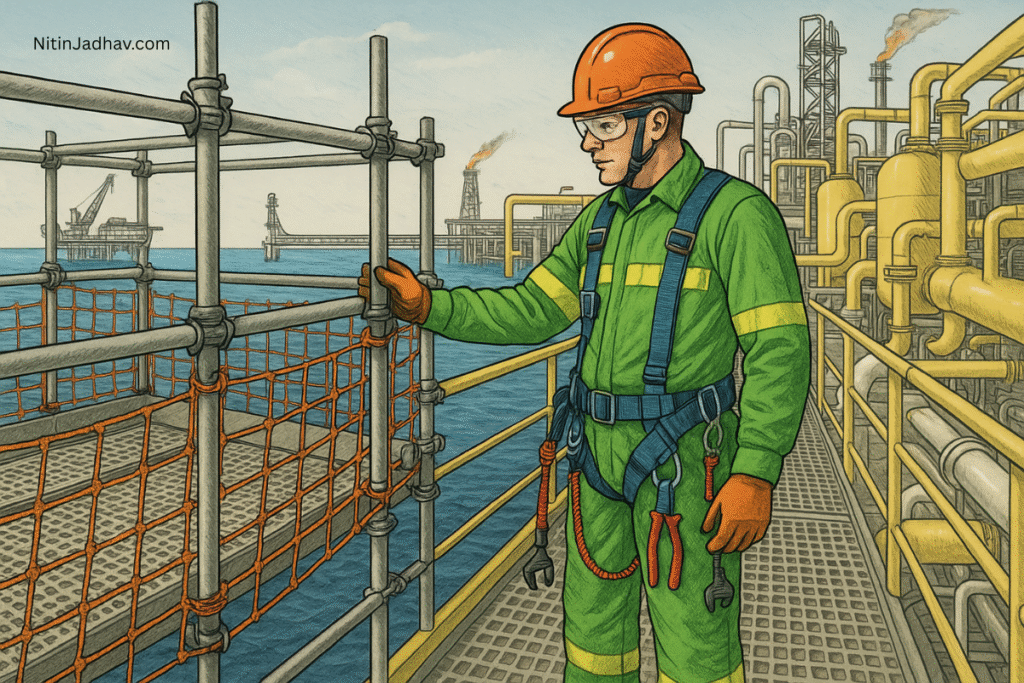

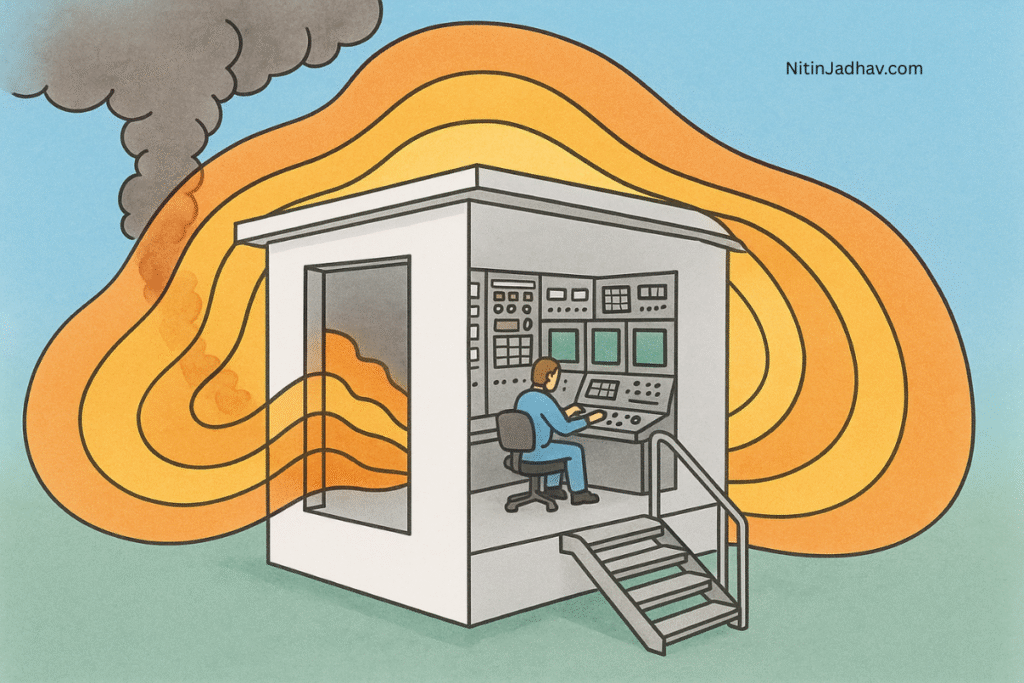

In high-hazard industries like oil & gas, petrochemicals, LNG, power, and chemicals, managing risk is not optional—it’s mission-critical. This section offers comprehensive coverage of:

-

Qualitative and quantitative risk assessments (QRA)

-

Hazard identification techniques (HAZID, HAZOP, FMEA)

-

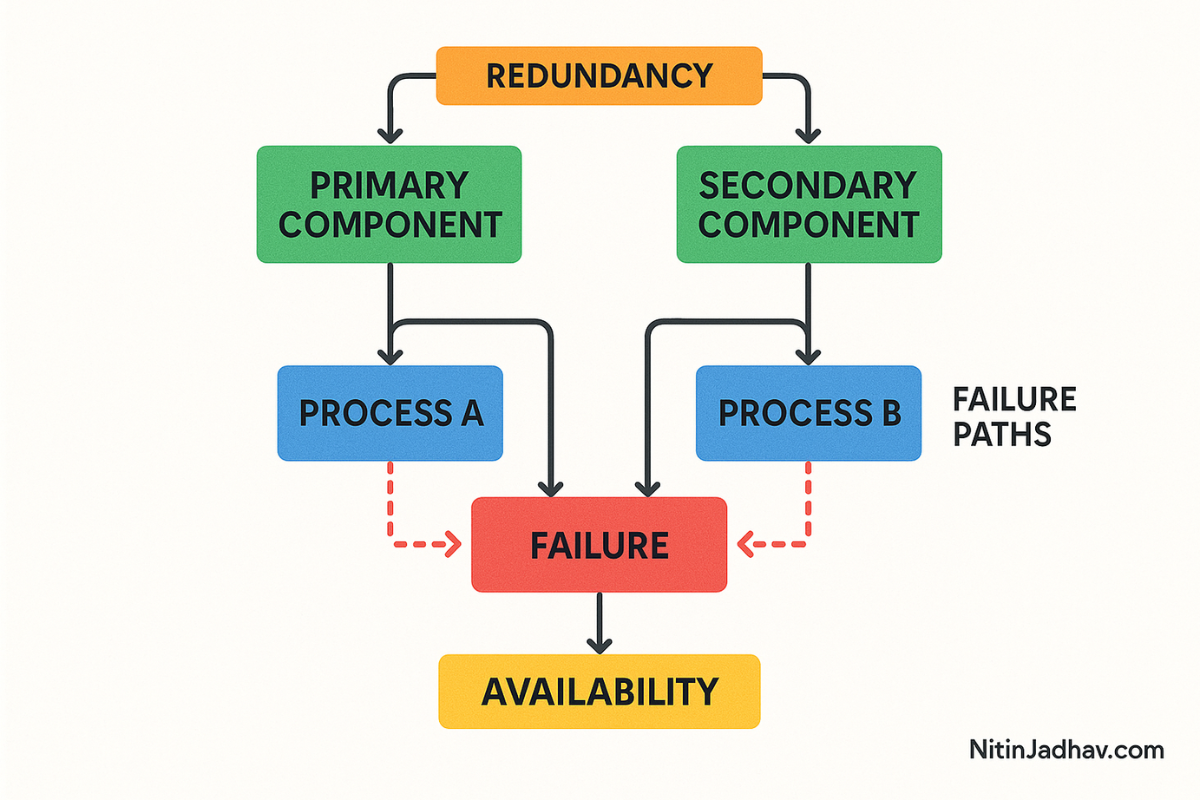

Layer of Protection Analysis (LOPA)

-

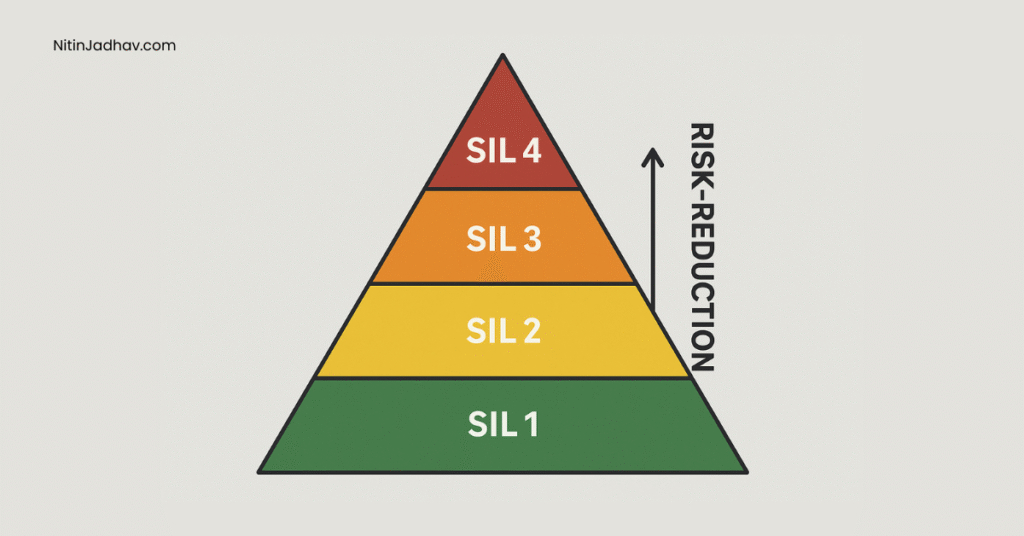

Safety Integrity Level (SIL) studies

-

Consequence and frequency analysis

-

Risk matrices, tolerability criteria, and risk ranking

-

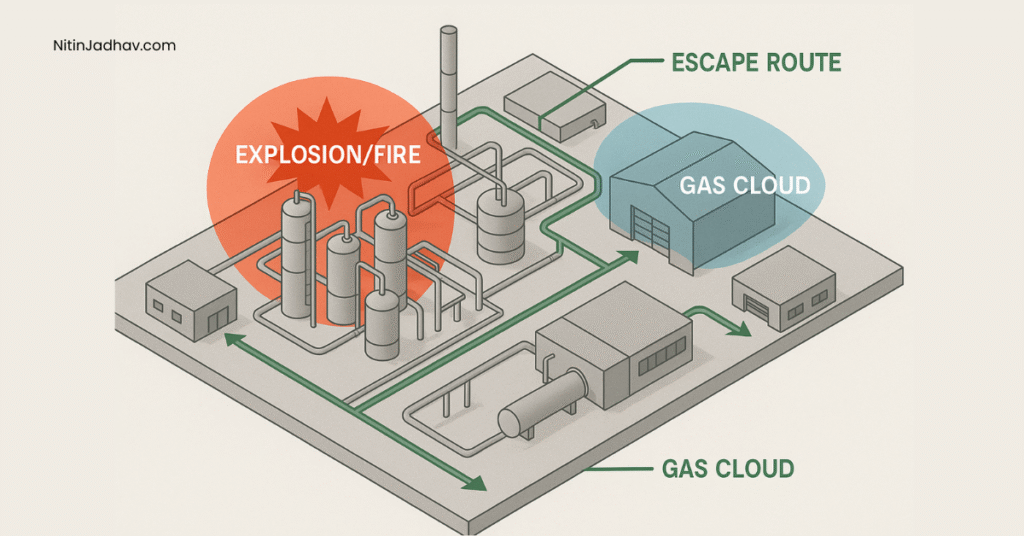

Fire, explosion, and toxic gas release modeling

-

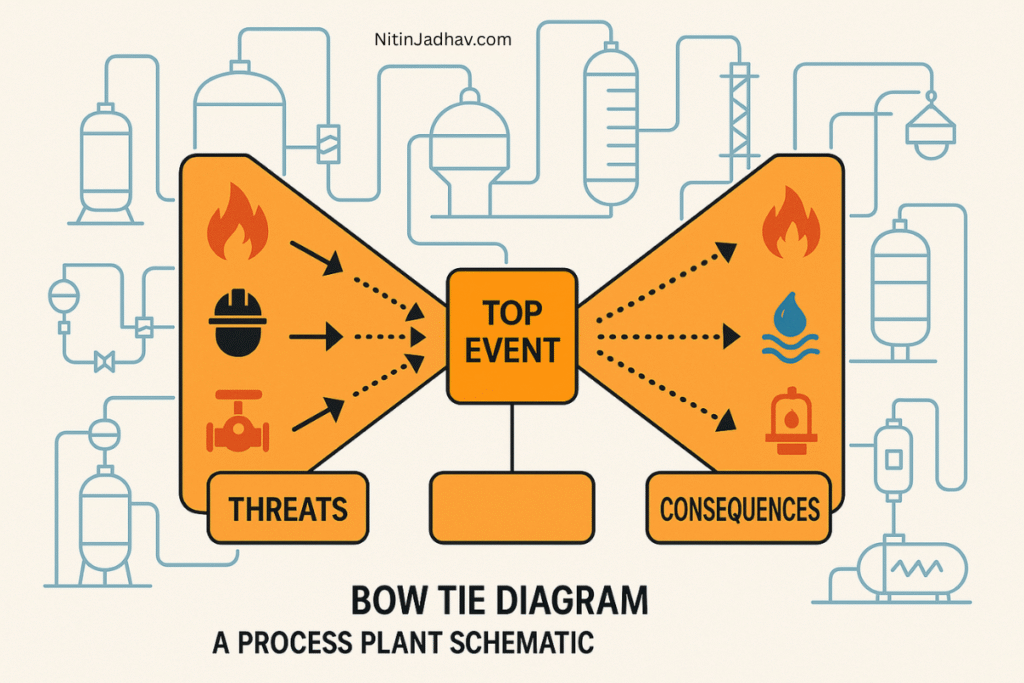

Bowtie analysis and ALARP demonstration

Each article provides practical frameworks, regulatory references, Excel tools, and software integrations (like PHAST, Safeti, PHA-Pro, DNV GL) based on global standards including CCPS, IEC 61511, OISD, NFPA, API, and ISO 31000.

Whether you’re a process safety engineer, risk analyst, HSE leader, or plant manager, this section helps you build risk-informed decision-making processes, design safer systems, and meet project-specific or organizational risk tolerance levels.

Our aim is to empower you to shift from reactive problem-solving to proactive risk prevention and mitigation.